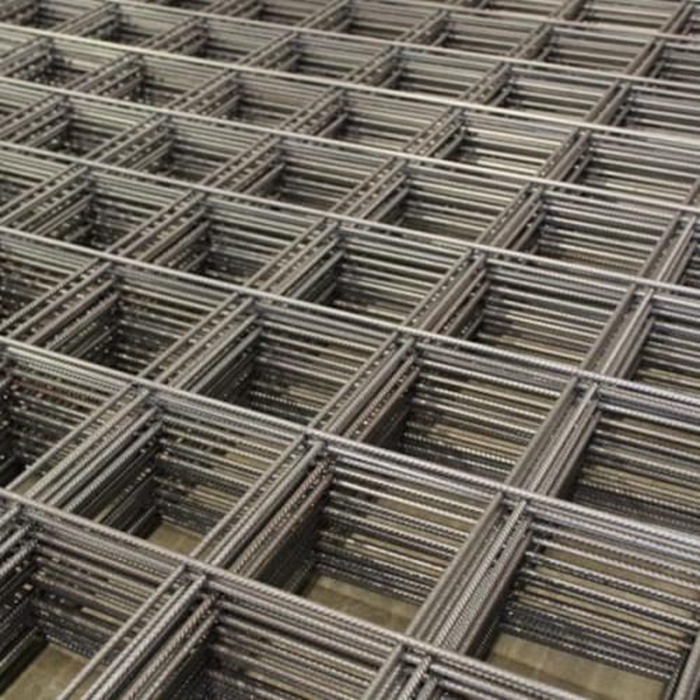

8 x 4 galvanized reinforcing concrete rebar welded wire mesh panel

8 x 4 galvanized reinforcing concrete rebar welded wire mesh panel

|

All specifications products can be customized according to customer requirements

|

|

|

Product name

|

Reinforcing Mesh

|

|

Standard

|

ASTM AISI JIS Etc

|

|

Grade

|

HRB335/400/500 Etc

|

|

Length

|

1-12m or customized

|

|

Width

|

1-12m or customized

|

|

Diameter

|

6-12mm or customized

|

|

Spacing

|

50/100/150/200 or customized

|

|

Texture of material

|

Q195 Q235 Q355 Etc

|

|

Tolerance

|

±1%

|

|

Processing Service

|

Bending, Welding, Decoiling, Cutting, Punching We accept custom orders of various sizes.

|

|

Technique

|

Hot rolled Welding

|

|

Delivery Time

|

Usually within 7 days, timed according to the number of customers.

|

|

Payment method

|

T/T, D/A, D/P, L/C, Western Union, MoneyGram or according to customer requirements

|

|

MQQ

|

1 Ton and available sample

|

|

Application

|

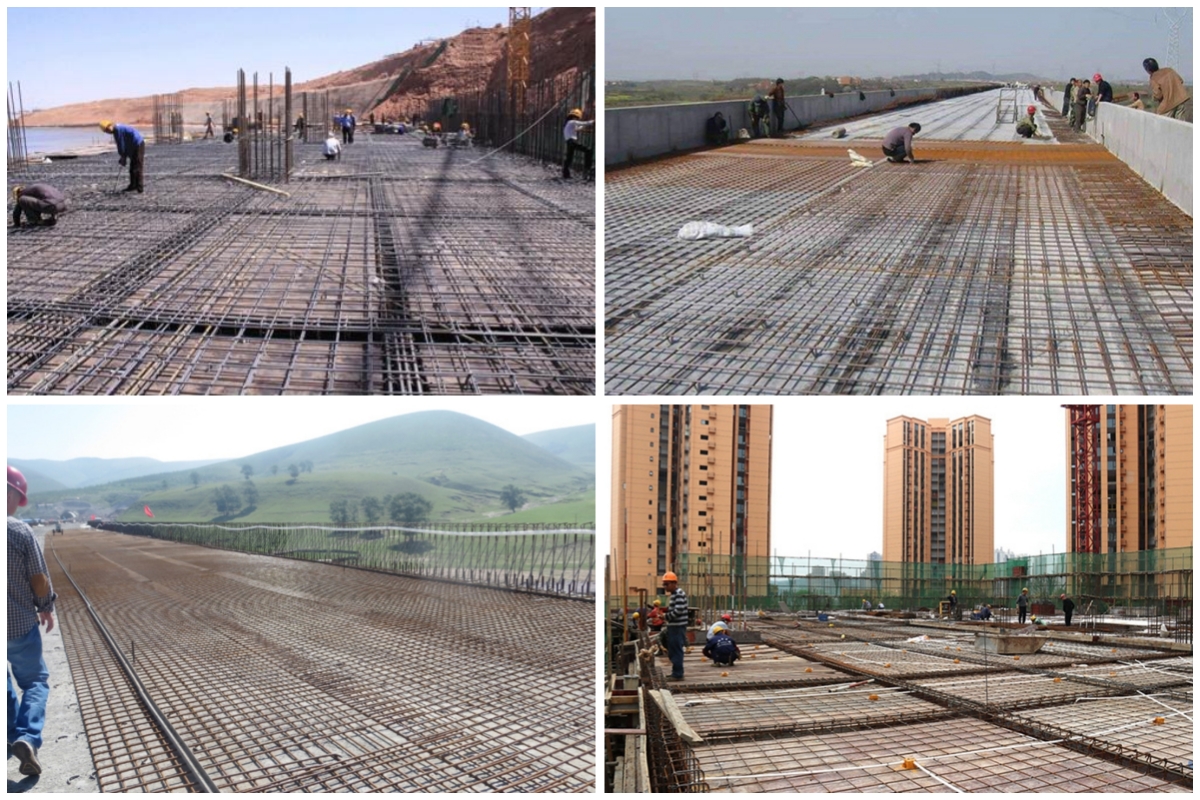

industry, agriculture, aquaculture, building, communication and transportation and mineral extraction,etc.

|

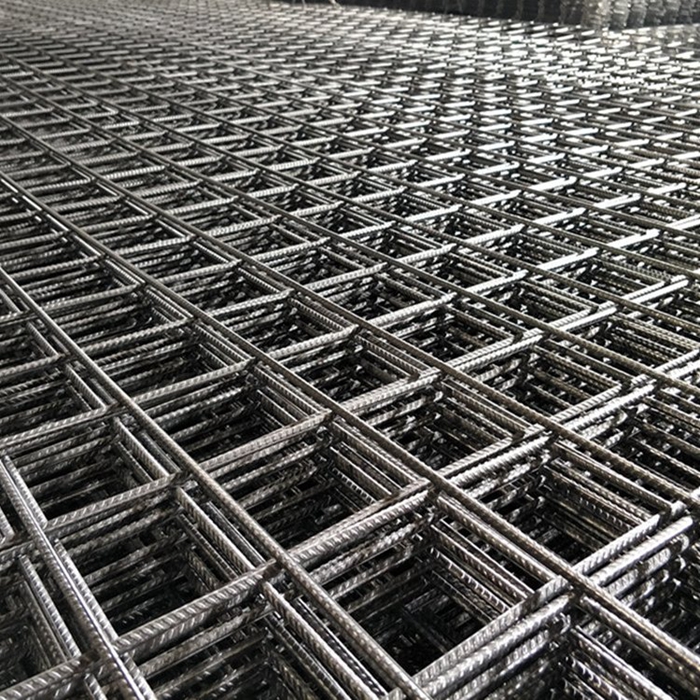

Feature

1. Special, good earthquake resistance and crack resistance. The mesh structure formed by the longitudinal bars and transverse bars of the reinforcing mesh is firmly welded. The bonding and anchoring with the concrete is good, and the force is evenly transmitted and distributed.

2. The use of reinforcing mesh in construction can save the number of steel bars. According to actual engineering experience, the use of reinforcing mesh can save 30% of the steel bar consumption, and the mesh is uniform, the wire diameter is accurate, and the mesh is flat. After the reinforcing mesh arrives at the construction site, it can be used directly without processing or loss.

3. The use of reinforcing mesh can greatly speed up the construction progress and shorten the construction period. After the reinforcing mesh is laid according to the requirements, the concrete can be poured directly, eliminating the need for on-site cutting, placing, and binding one by one, which helps to save 50%-70% of the time.

Application

CONTACT