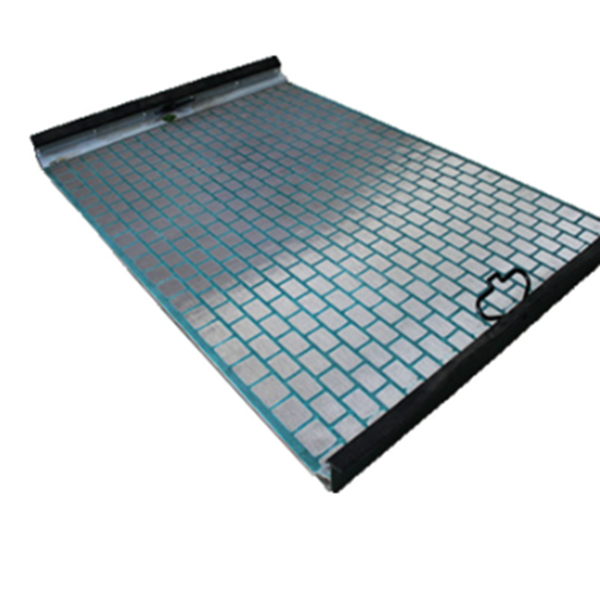

High efficiency Wear-resistant flat oil vibrating screen shale shaker screen

High Efficiency Wear-Resistant Flat Oil Vibrating Screen Shale Shaker Screen

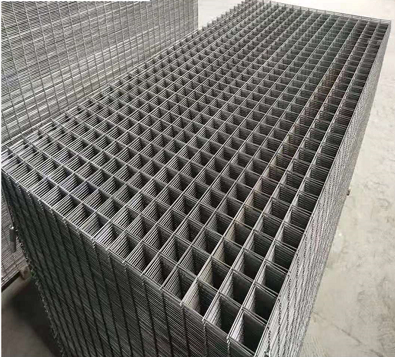

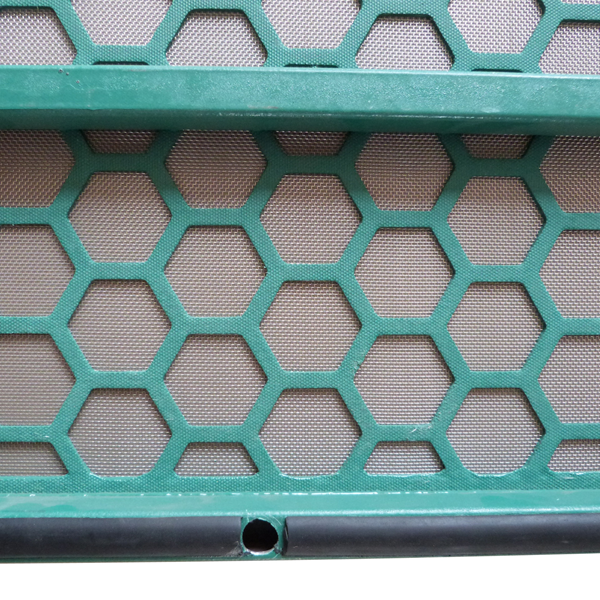

1. The mesh numbers of each layer of stainless steel mesh in the flat vibrating screen are different. Accurate and reasonable matching can make the screening effect more detailed. The mesh numbers of the stainless steel mesh and the punching shape and opening rate of the metal lining plate are different. size, and strive to obtain the largest effective filtration area while ensuring the intensity of use.

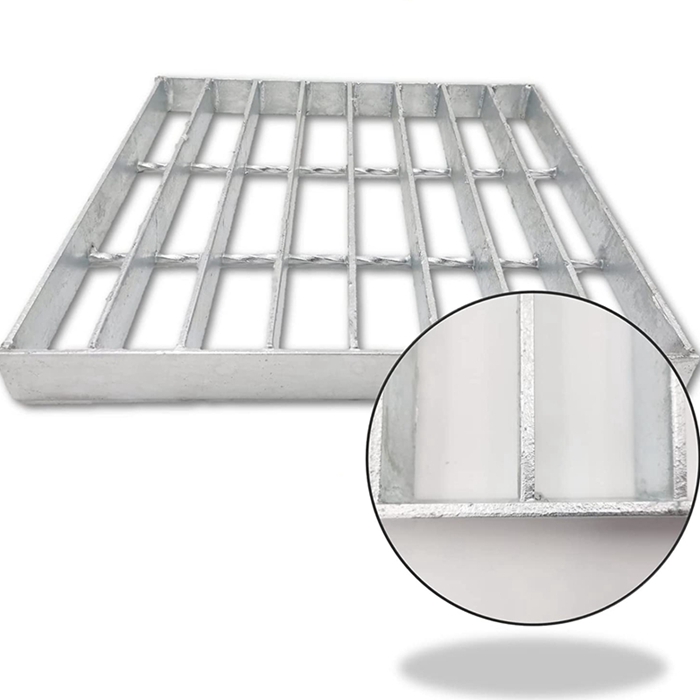

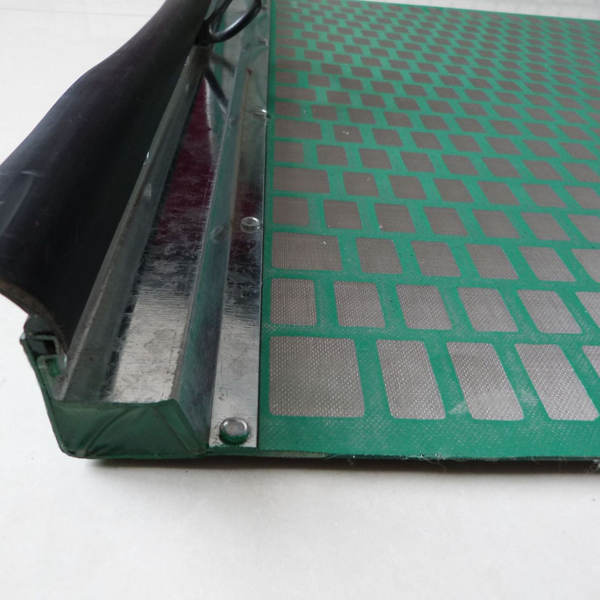

2. The stainless steel screen and the metal lining are tightly bonded into one, which enhances the strength of the entire flat vibrating screen and prolongs its use time.

Features

3. The mesh of the metal lining plate divides the stainless steel screen into multiple independent small mesh surfaces, which can prevent excessive expansion of local damage. At the same time, it is equipped with a special rubber match to repair the damaged mesh surface, which can save time and reduce usage costs.

Our company has rich production experience and mature technology and can produce various specifications of flat vibrating screens according to the needs of different customers.

Flat plate vibrating screen (hook edge vibrating screen) is currently the most commonly used vibrating screen and can be widely used in drilling operations under different conditions.

Usually, a flat vibrating screen is composed of 2 to 3 layers of stainless steel screens bonded to a perforated metal lining. The characteristics of this type of vibrating screen are as follows:

Specification

| Screen model |

Mesh range |

Dimensions (width x length) |

Suitable vibrating screen machine models |

| HSP-1 | 20-325 | 697×1053mm | D2000 |

| HSP-2 | 20-325 | 695×1050mm | D500 |

| HSP-3 | 20-325 | 697× 846 mm | D313M |

| HSP-4 | 20-325 | 903×1155mm | BEM-3 |

| HSP-5 | 20-325 | 1212×1141mm | ALS-2 |

| HSP-6 | 20-325 | 915×1150mm | LCM-2D |

| HSP-7 | 20-325 | 700×1165mm | S250 |

| API RP 13C(ISO 13501) | |

| D100 sieved particles (microns) | API screen number |

| >780.0 to 925.0 | API 20 |

| >655.0 to 780.0 | API 25 |

| >550.0 to 655.0 | API 30 |

| >462.5 to 550.0 | API 35 |

| >390.0 to 462.5 | API 40 |

| >327.5 to 390.0 | API 45 |

| >275.0 to 327.5 | API 50 |

| >231.0 to 275.0 | API 60 |

| >196.0 to 231.0 | API 70 |

Application

Contact Us

22nd, Hebei Filter Material Zone, Anping, Hengshui, Hebei, China

Contact us