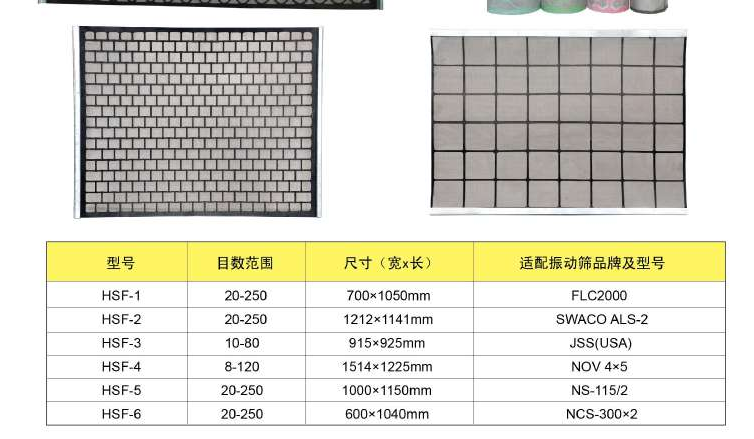

High temperature resistant stainless steel composite mesh oil vibrating screen

High Temperature Resistant Stainless Steel Composite Mesh Oil Vibrating Screen

Features

Application

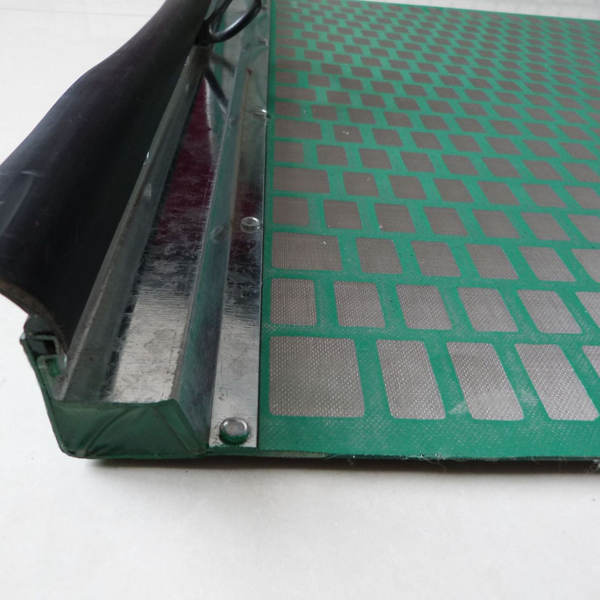

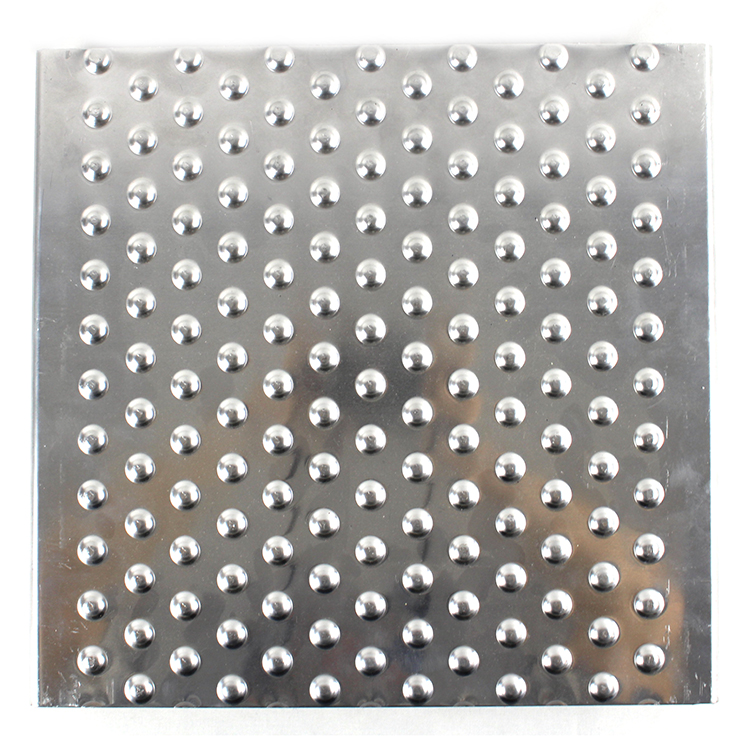

The oil drilling fluid vibrating screen is a metal mesh structural element used for screening and filtration. It is widely used in screening, filtration, dehydration, desliming and other operations in many industries. It has high strength, rigidity and load-bearing capacity, and can be made into rigid screening and filtering devices of various shapes. Easy to leak, wear-resistant and corrosion-resistant. The cross section of the mesh is trapezoidal, with the gap narrow at the top and wide at the bottom. It is a newly developed product in the wire mesh industry. There are low carbon steel wire, high manganese steel wire and stainless steel wire.

FAQ

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

You can make the payment to our bank account, Western Union or PayPal:

30% deposit in advance, 70% balance against the copy of B/L.

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

CONTACT