In many fields such as industrial production, building protection, agricultural fencing and home decoration, welded mesh has become one of the indispensable materials with its excellent structural strength and wide applicability. The key to the stability and durability of welded mesh in various environments lies in its unique and exquisite structural design. This article will deeply analyze the structural strength of welded mesh and reveal the secret behind its toughness.

1. Manufacturing process and basic structure of welded mesh

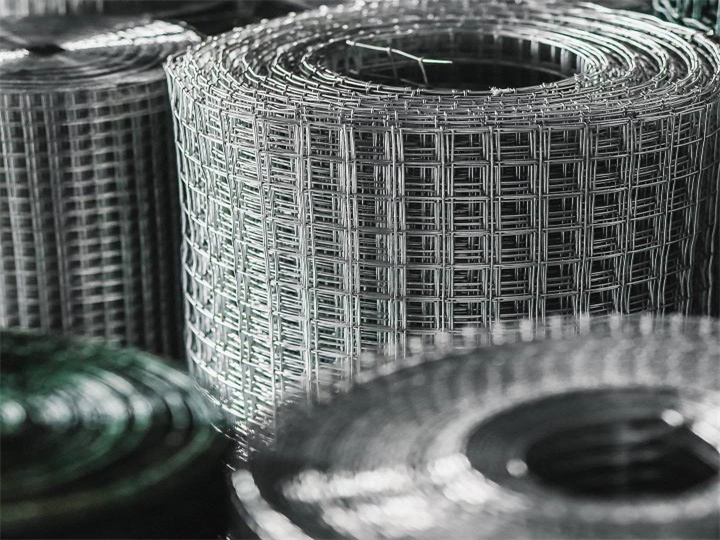

As the name suggests, welded mesh is a mesh structure formed by cross-welding metal wires together through electric welding. In this process, the metal wires melt at high temperatures and connect tightly to form strong nodes. These nodes not only enhance the stability of the mesh, but also ensure the bearing capacity of the welded mesh when facing external force impact.

The basic structure of welded mesh usually includes the mesh size, the diameter of the metal wire and the layout of the welding points. The mesh size determines the permeability of the welded mesh, while the diameter of the metal wire directly affects its load-bearing capacity. The layout of welding points is related to the overall strength and durability of the welded mesh. Reasonable welding layout can effectively disperse external forces and avoid damage caused by local stress concentration.

2. Core elements of structural strength

Material and diameter of metal wire: Common metal materials for welded mesh include low-carbon steel wire, stainless steel wire and galvanized steel wire. Metal wires of different materials have different strengths and corrosion resistance. The larger the diameter of the metal wire, the stronger the load-bearing capacity of the welded mesh, but the permeability will be reduced accordingly. Therefore, when choosing a welded mesh, it is necessary to balance these two factors according to the specific application scenario.

Welding process and node strength: The welding process of the welded mesh is crucial to its structural strength. High-quality welding can ensure a firm connection between the metal wires and form stable nodes. These nodes can effectively transmit and disperse stress when subjected to external forces to avoid deformation or breakage of the mesh. In addition, the number and layout of welding points will also affect the overall strength of the welded mesh. Reasonable welding layout can further improve the stability and durability of the welded mesh.

Grid design and application adaptability: The grid design of the welded mesh not only affects its aesthetics, but is also closely related to structural strength. Smaller meshes can provide better protection, but may sacrifice a certain degree of permeability. Therefore, when designing welded mesh, it is necessary to select the appropriate mesh size according to the needs of the application scenario. At the same time, the mesh design of the welded mesh should also consider the convenience of its installation and maintenance to ensure its stability and reliability in long-term use.

3. Practical application of the structural strength of welded mesh

The structural strength of welded mesh has been widely used in many fields. In the construction field, welded mesh is used as wall reinforcement, floor support and protective fence, and its sturdy structure can withstand large loads and impact forces. In the agricultural field, welded mesh, as a fencing material, can effectively prevent animal escape and foreign invasion, and protect the safety of crops and livestock. In addition, welded mesh also plays an irreplaceable role in transportation, mining, home decoration and other fields.

Post time: Jan-24-2025