Traditional operating platforms are all laid with patterned steel plates on steel beams. Operating platforms in the chemical industry are often placed in the open air, and the production environment of the chemical industry is highly corrosive, which makes it easy for the strength and rigidity to be rapidly weakened due to rust, and the service life is greatly reduced. At the same time, smaller welds are also prone to lose strength, which can easily cause safety hazards. Patterned steel plates need to be rusted and painted on site, which requires a large workload and the construction quality is not easy to be guaranteed; patterned steel plates are prone to deformation and depression, causing water accumulation and rust, and comprehensive anti-corrosion maintenance is required every three years to ensure their performance. The chemical production industry, which has strict control requirements for flammable and explosive items, brings many inconveniences and even affects daily production

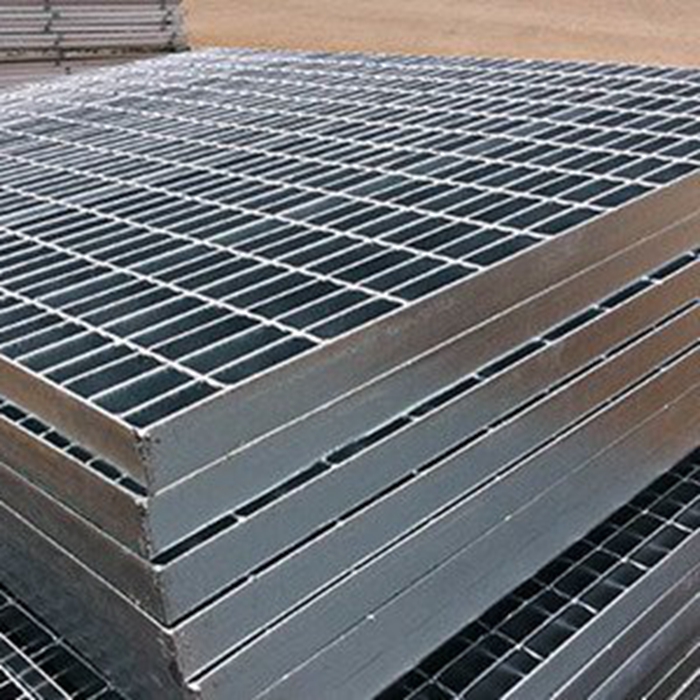

In recent years, steel gratings can alleviate and solve this problem to a large extent. The use of steel gratings in the operating platforms of petrochemical units has obvious advantages and a very broad application prospect. Steel grating, also known as steel grid plate, is a kind of steel product with square grids in the middle, which is made of flat steel arranged in a certain spacing and cross bars, and is welded or locked by pressure. It is mainly used for ditch covers, steel structure platform plates, and treads of steel ladders. It can also be used as filter gratings, trestles, ventilation fences, anti-theft doors and windows, scaffolding, equipment safety fences, etc. It has ventilation, lighting, heat dissipation, anti-slip, explosion-proof and other properties.

Due to the existence of the spacing between the flat steel of the steel grating plate, the sparks generated during the hot work cannot be blocked. From the perspective of the steel grating currently used, the gap between the flat steels is greater than 15mm. If the gap is 15mm, nuts below M24, bolts below M8, round steel below 15 and welding rods, including wrenches, may fall; if the gap is 36mm, nuts below M48, bolts below M20, round steel below 36 and welding rods, including wrenches, may fall. Small objects falling may injure people below, causing personal injury; instruments, cable lines, plastic pipes, glass level gauges, sight glasses, etc. in the device may be damaged, causing accidents caused by interlocking of production devices and material leakage. Due to the existence of the spacing of steel gratings, rainwater cannot be blocked, and materials leaking from the upper floor directly drip onto the first floor, increasing the harm to people below.

Although steel gratings have many advantages over traditional patterned steel plates, such as economy and safety, and high performance-price ratio, suitable steel grating models should be selected as much as possible during design and selection, but in actual applications, steel gratings can be mixed with patterned steel plates to meet more reasonable structural requirements, production needs and achieve more obvious economic benefits.

According to the above situation, the following principles should be followed when using patterned steel plates and steel gratings on steel structure floors. When the device frame is a steel structure, steel gratings are preferred for floors and stair treads. Patterned steel plates are preferred in building aisles, mainly to facilitate the passage of people with acrophobia. When the equipment and piping are densely packed in the frame, patterned steel plate floors should be used, mainly because steel gratings are not easy to be processed into arcs. Unless they are customized, it will affect the overall strength of the steel gratings. When waterproofing is required between floors, patterned steel plate floors should be used, at least the top floor should be patterned steel plates. When equipment and pipelines need to be frequently inspected, patterned steel plate floors should be used to reduce the risk of falling objects that may occur during inspection and maintenance operations. Patterned steel plates should be used for high (>10m) county viewing platforms to reduce the impact of people's fear of heights.

Post time: May-29-2024