Compared with other types of building materials, steel gratings have the advantages of saving materials, reducing investment, simple construction, saving construction time, and durability. The steel grating industry is becoming an important part of China's steel structure industry. The use of steel gratings is becoming an increasingly common phenomenon in steel structure construction. How to extend the service life of steel gratings and maximize investment and return rate is a topic of research for many companies. Let's talk about a few suggestions that affect the service life of steel gratings.

Materials and production

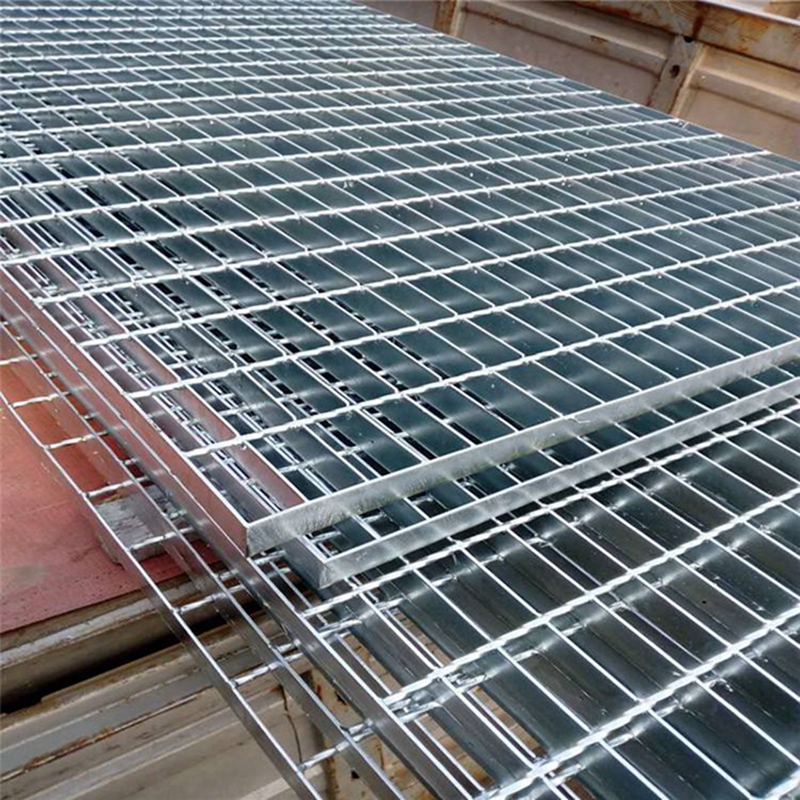

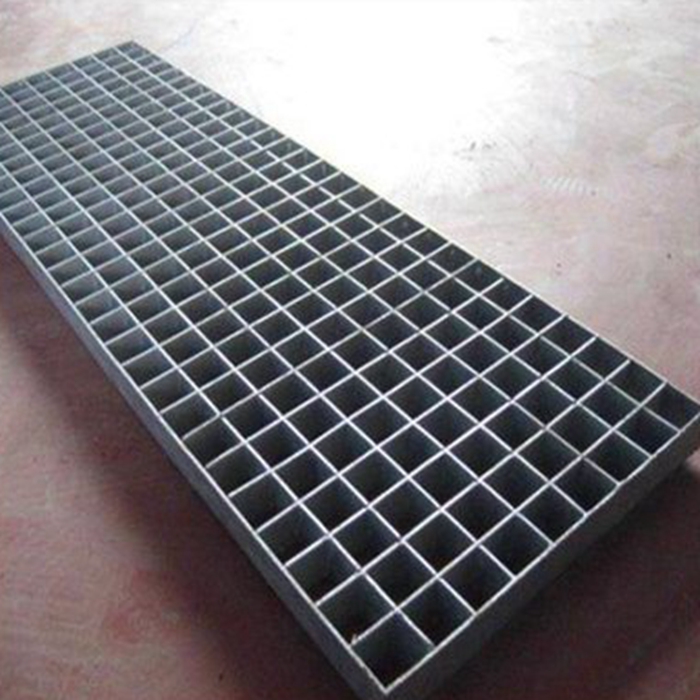

The chemical composition and mechanical properties of steel grating raw materials are important criteria for measuring the quality of steel gratings. Only high-quality raw materials can produce high-quality steel grating products. The life of high-quality steel grating products is guaranteed. The material of steel grating raw materials is the primary condition to ensure the mechanical properties of steel gratings. The various parameters of steel grating raw materials (material, width, thickness) must be strictly controlled so that the steel grating produced can have a longer life. The first choice for steel grating procurement is press-welded steel gratings. The flat steel of press-welded steel grating materials has no punching holes, the load-bearing capacity is not weakened, and the mechanical properties are higher. Pressed welded steel gratings are machine-welded, with good consistency and stronger welds. Pressed welded steel gratings have good flatness and are easy to install. Pressed welded steel gratings are machine-welded, and there is no welding slag, which makes them more beautiful after galvanizing. The use of press-welded steel gratings is more guaranteed than purchasing artificial steel gratings, and the service life will be longer.

Load-bearing design

The load requirements of steel gratings are proposed by the design department and the user, or the design department and the user directly select the specifications of the steel gratings. The calculation of the relationship between the load, span and deflection of the steel grating is carried out according to the principles of steel structure calculation. The load design of the steel grating requires that if there is a cut in the steel grating, the remaining area of the steel grating should be able to meet the requirements of the design load. Long-term use causes the specifications of the steel grating to change, resulting in insufficient structural bearing capacity. Therefore, the steel grating must not be overloaded. If overloaded, the steel grating will be deformed, and in severe cases, it will be welded or even damaged, seriously affecting the life of the steel grating. In order to make the steel grating last longer, the load-bearing margin should be designed according to the use environment during design and purchase to ensure the service life of the steel grating.

External corrosion

Due to the erosion of chemical substances and electrochemical corrosion, the cross-section of the steel grating components is weakened, so it is recommended to use hot-dip galvanizing surface treatment. The production process of hot-dip galvanizing of steel grating is a physical and chemical process in which the treated steel grating plated parts are immersed in molten zinc liquid to form a galvanized layer with an alloy layer and an intermelting layer on the metal surface of the steel grating. It is an economical and practical material protection process recognized by countries around the world. The weight and requirements after galvanizing should comply with the provisions of GB/T13912-2002. Hot-dip galvanizing treatment on the surface of the steel grating can increase the life of the steel grating.

Daily maintenance

It can be seen that there are many factors that affect the service life of the steel grating. If you want to extend the service life of the product, you must pay attention to maintenance work. Daily maintenance can make the steel grating last longer.

Post time: Jun-21-2024