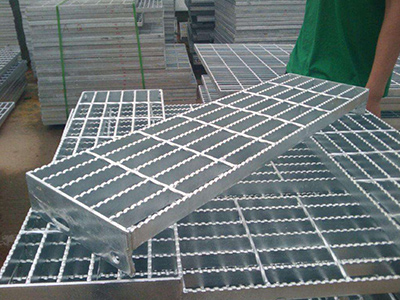

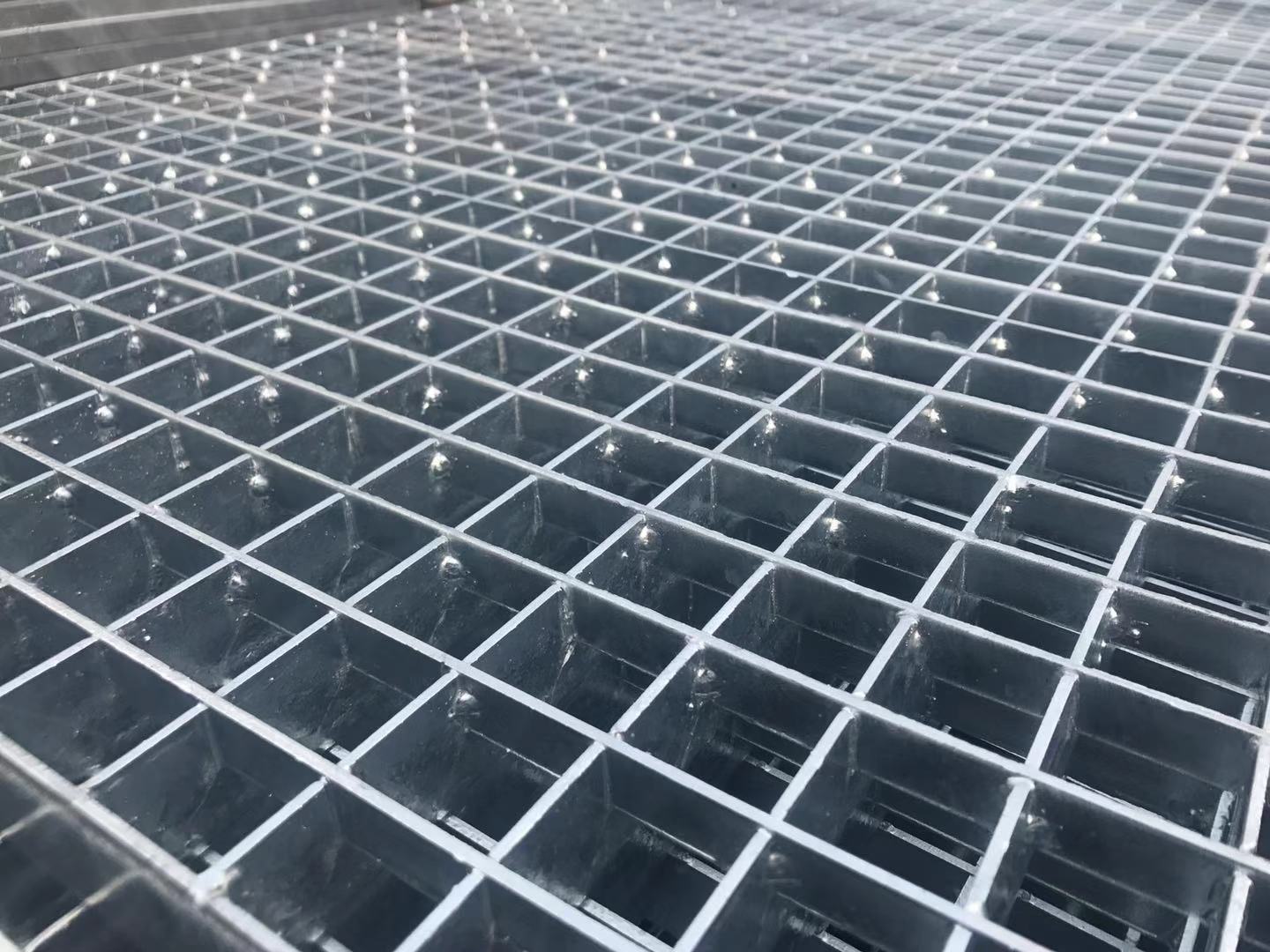

Steel grating is widely used in various fields of industry, and can be used as industrial platforms, ladder pedals, handrails, passage floors, railway bridge sideways, high-altitude tower platforms, drainage ditch covers, manhole covers, road barriers, three-dimensional parking Fields, institutions, schools, factories, enterprises, sports fields, garden villas fences, can also be used as residential windows, balcony guardrails, highways, railway guardrails, etc.

It is widely used, so have you installed it yourself? Can I install it myself if I don't have a professional technician? Read on to find out about these questions.

1. Directly weld the steel grating on the supporting steel structure, and brush the zinc-rich powder paint twice on the welding place.

2. Use the special installation clips for steel gratings to install, without damaging the galvanized layer, and easy to disassemble and assemble. Each set of installation clips includes an upper clip, a lower clip, one M8 round head bolt and one nut.

3. According to the needs, fastening methods such as stainless steel mounting clips or bolt connections can be provided.

4. The installation gap of the steel grating is generally 100mm.

5. When installing the steel grating, be sure to pay attention to the firmness and reliability of the installation. Check frequently to prevent the installation clip from loosening and falling off. Weld or add rubber pads near the vibrating steel grating.

At the same time, we should also pay attention to some problems in the installation of steel grating:

1. The steel grating shall be checked and accepted in combination with the drawing design before installation, and those that fail the acceptance cannot be put into engineering use.

2. Determine the installation sequence before installing the steel grating, and install it in sequence according to the drawing number.

3. When installing the steel grating, it is necessary to determine the direction of the flat steel and the bearing direction. The installation process must be laid from the first layer of steel ladder structure to the surrounding.

4. It is stipulated that each steel grating must be equipped with at least 2 sets of mounting clips. When the welding is completed, the welding contact points must be painted to prevent rust.

5. One piece of steel grating must be fixed, and it is strictly forbidden to stand on the unfixed steel grating when working at heights.

6. When working on steel gratings at heights, installers should fasten their safety belts and take protective measures.

7. It is strictly forbidden to work at heights on the steel grating. The installer has small tools and accessories (wrench, welding rod, etc.) in his pocket to avoid falling and hurting people.

Post time: Apr-19-2023