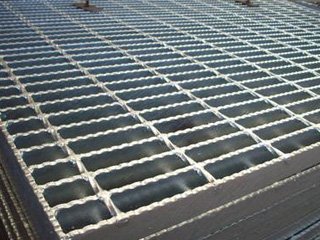

Steel grating is generally made of carbon steel, and the surface is hot-dip galvanized, which can prevent oxidation. Can also be made of stainless steel. Steel grating has ventilation, lighting, heat dissipation, anti-skid, explosion-proof and other properties. Due to the many advantages, steel gratings are already everywhere around us, let me take you to have a look.

Steel gratings are widely used in petrochemical, electric power, tap water, sewage treatment, port terminals, architectural decoration, shipbuilding, municipal engineering, sanitation engineering and other fields. It can be used on the platform of petrochemical plants, the stairs of large cargo ships, the beautification of residential decoration, and the drainage cover of municipal engineering.

It can be said that steel grating has penetrated into every corner of our life and production. With the further improvement of the country's overall national strength, steel grating will have greater development. The surface treatment of steel grating includes hot-dip galvanizing, electro-galvanizing (cold galvanizing), dipping, painting and other key processes.

However, the two most commonly used at present are hot-dip galvanizing and cold-dip galvanizing. Since the service life of the two is very different, if you can't tell the difference, it is easy to be deceived.

Today I will teach you a simple method: observe the appearance, you can find that the surface of hot-dip galvanized steel grating is black, and the surface of cold-dip galvanized steel is shiny. This is a relatively quick and simple way to judge. You can make a simple judgment by yourself after receiving the goods. Of course, if you are not sure about the product quality, you are welcome to communicate with us, Anping Tangren is happy to help you, and we also believe that our product quality can satisfy you.

CONTACT

Anna

Post time: May-09-2023