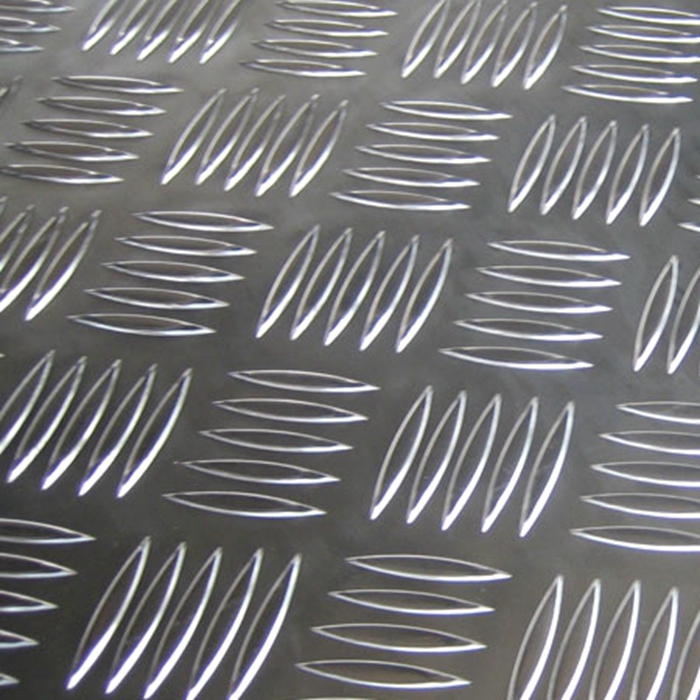

Pattern anti-skid plates are also the most important member of the anti-skid plate family and are favored by many users. Pattern anti-skid plate The steel plate with patterns on the surface is called pattern plate. The patterns are lentil-shaped, diamond-shaped, round bean-shaped, and oblate-shaped mixed shapes. The lentil-shaped is the most common on the market. Patterned plates have many advantages such as beautiful appearance, anti-slip, enhanced performance, and steel saving. They are widely used in transportation, construction, decoration, bottom plates around equipment, machinery, shipbuilding and other fields. Generally speaking, users do not have high requirements for the pattern shape, mechanical properties, and mechanical properties of pattern plates. Therefore, the quality of pattern plates is mainly reflected in the pattern formation rate, pattern height, and pattern height difference. Currently, the commonly used thicknesses on the market range from 2.0-8mm, and the common widths are 1250 and 1500mm.

The anti-skid plates produced by the pattern anti-skid plate manufacturers include iron plates, aluminum plates, etc., with thicknesses ranging from 1mm to 3mm. The hole types can be divided into flange type, crocodile mouth type, drum type, etc. The anti-skid plates have extremely good anti-slip properties and Aesthetically pleasing, it is widely used in industrial plants, production workshops, transportation facilities, etc.

Pattern anti-skid plate material: ordinary iron plate, stainless steel plate, aluminum plate, aluminum alloy plate and other metal plates can be customized with other materials or specifications and hole shapes.

Characteristics of the patterned anti-skid plate: It is anti-slip, rust-proof and anti-corrosive and is durable and beautiful in appearance. The punching hole types include raised herringbone, raised cross flower, round, crocodile mouth and teardrop types, all of which are CNC punched. .

Patterned anti-skid plate Use: Suitable for outdoor use in sewage treatment, tap water, power plants and other industrial industries. Stair treads are also used for mechanical anti-skid and indoor decoration anti-skid.

There are two production processes for pattern anti-skid plates: 1) Hot-embossed patterns are usually sheared, bent, welded and formed according to different uses (the iron plate can be hot-dip galvanized for anti-rust treatment).

According to the hole type, anti-skid plates are divided into: crocodile-mouth anti-skid plates (crocodile anti-skid plates), herringbone anti-skid plates, round anti-skid plates, and teardrop-shaped anti-skid plates.

Anti-skid plates are divided according to material: stainless steel anti-skid plates, ordinary anti-skid plates, and aluminum anti-skid plates.

Post time: Mar-21-2024