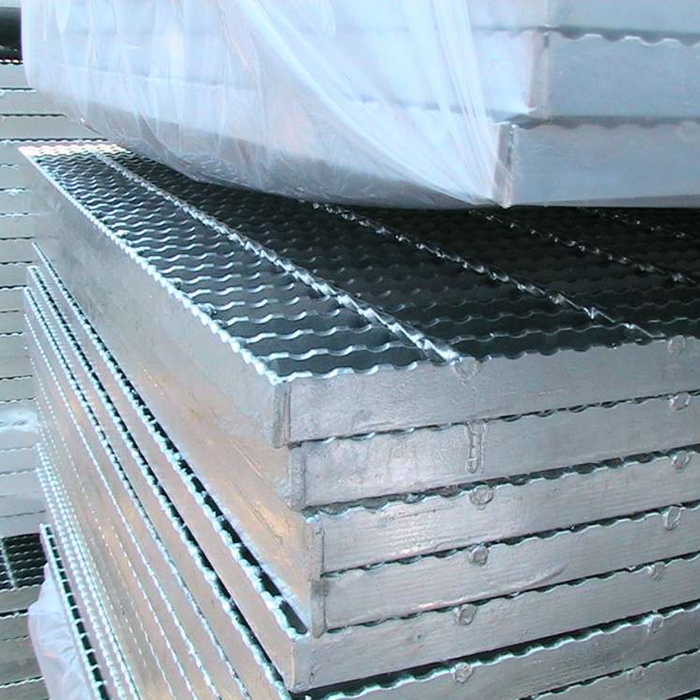

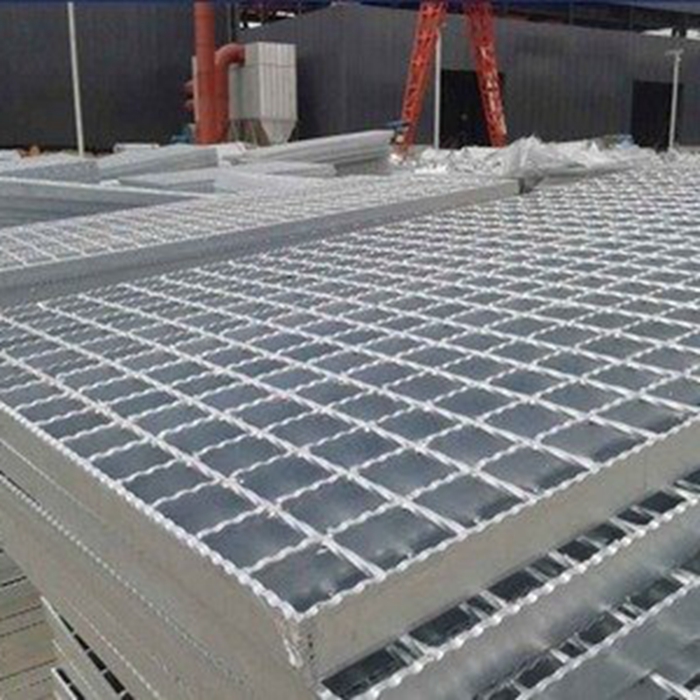

Hot-rolled anti-skid flat steel is one of the main raw materials for steel grating manufacturing. Steel grating is welded and assembled into a grid-shaped plate by flat steel. After galvanizing, it is widely used in power plants, boiler plants, chemical plants, protective covers for power communication channels on highways, automobile spray paint rooms, municipal facilities, etc. It has the advantages of firmness, beauty, and ventilation. The traditional anti-skid steel plate with mesh pattern has been gradually replaced by steel grating due to its shortcomings such as easy to change shape, airtightness, easy to accumulate water and rust, and difficult construction. In order to make the steel grating have the effect of anti-skid, a tooth shape with certain requirements is made on one or both sides of the flat steel, that is, anti-skid flat steel, which plays an anti-skid role in use. The steel grating is mainly welded by flat steel, and twisted steel is used to connect them to fix the spacing and enhance the strength. After grinding, burr removal, galvanizing and other processing procedures, it is made into various specifications and sizes. At present, due to the development of my country's economic construction, the use of steel grating in all walks of life has become more common.

The cross-sectional shape of anti-skid flat steel

Anti-skid flat steel is a special-shaped section with periodic tooth shape and symmetrical special-shaped section. The cutting surface shape of steel has an economical section while meeting the use strength. The load-bearing shape of ordinary anti-skid flat steel is used in ordinary use places. Double-sided anti-skid flat steel is used in occasions where the front and back sides can be interchanged, such as the floor of the car spray paint room, which can improve the utilization rate. Anti-skid flat steel is a series of products. It can be divided into I type and ordinary type according to the cross-sectional shape. It can be divided into 5x25.5x32.5x38 and other specifications according to the cross-sectional size. The cross-sectional area ranges from 65 square meters to 300 square meters.

Deformation characteristics of anti-skid flat steel

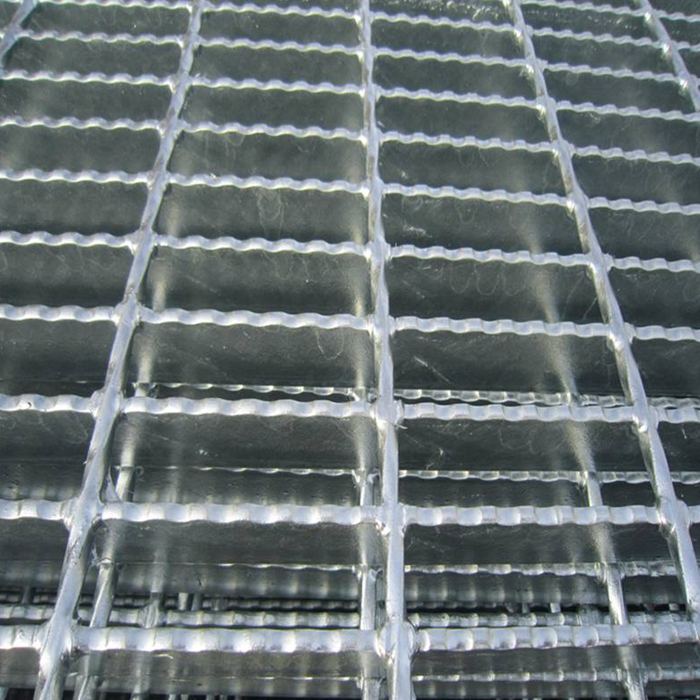

Compared with ordinary flat steel, anti-skid flat steel mainly has tooth shape and symmetrical type 1 cross-section. Deformation characteristics of tooth profile: The tooth profile is formed by one vertical rolling at the front hole of the finished product. During the forming process, the amount of pressure reduction at the root of the tooth is much greater than that at the top of the tooth. The uneven deformation causes drums on both sides of the groove bottom. When the hole of the finished product is flat-rolled in the subsequent process, the amount of metal in the drum shape is converted into local widening, which makes the tooth profile of the finished product after rolling and the tooth profile set by the vertical rolling hole before the finished product have a larger pitch. This pitch also changes with the change of the pressure reduction of the finished hole and the front hole of the finished product. To obtain the correct tooth profile, it is necessary to reasonably determine the pressure reduction and hole design of the finished hole and the front hole of the finished product, master the deformation law, and design the roller tooth profile of the front hole of the finished product that meets the product requirements and can be mass-produced with stable quality.

Post time: Jul-08-2024