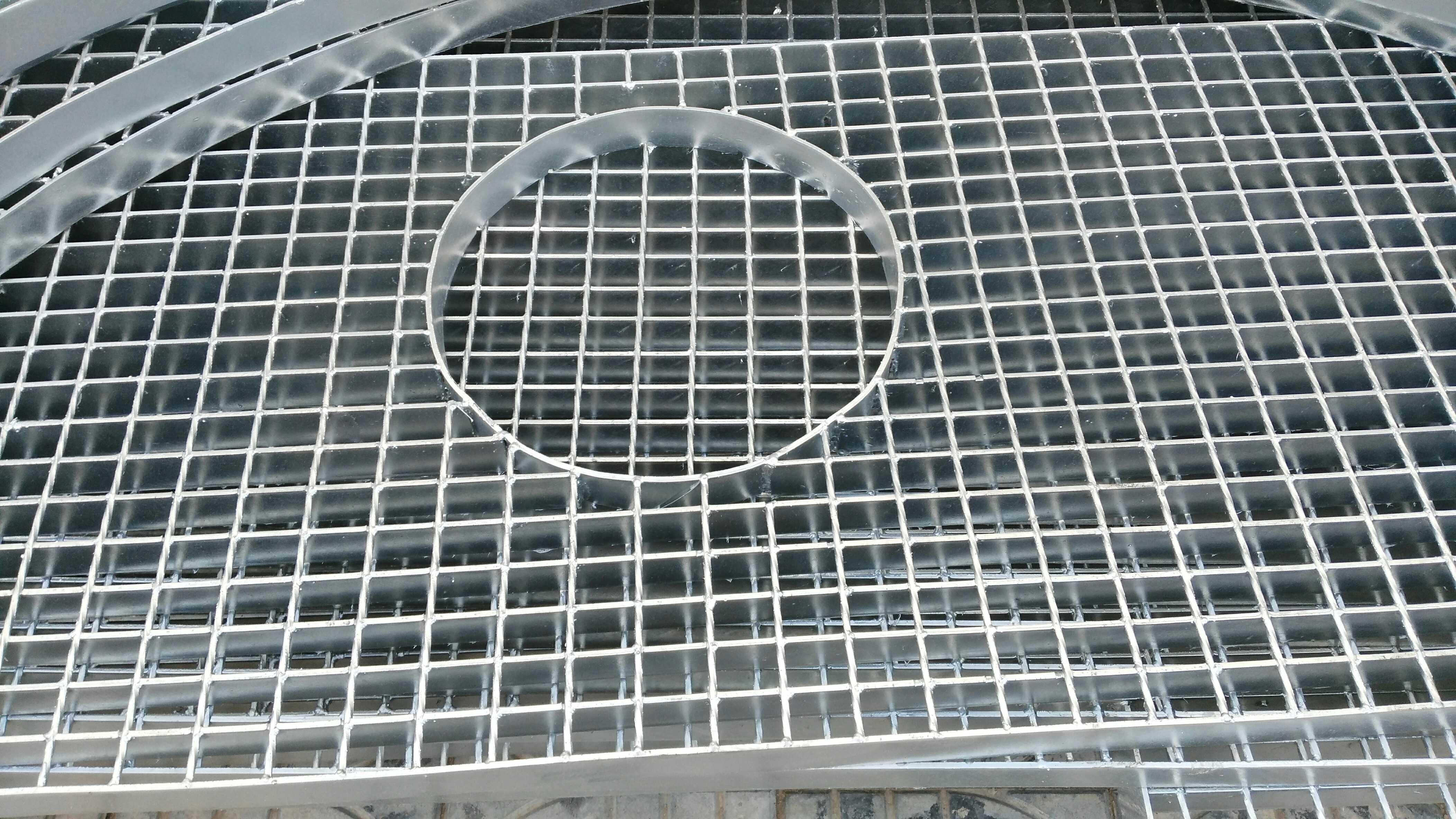

In order to extend the service life of steel gratings, the surface can be hot-dip galvanized, cold-dip galvanized, or spray-painted. The most corrosion-resistant steel grating is hot-dip galvanized steel grating. Hot-dip galvanized steel grating is a method commonly used by users. If there is a large amount of garbage on the surface of the steel grating, the service life of the steel grating will be shortened. For example, the dirt remaining on the steel ladder treads and trench covers requires us to clean and maintain the steel gratings.

Long-term maintenance of steel grating is very important. You must develop a good habit of regular cleaning and inspection. With proper maintenance, hot-dip galvanized steel grating can generally be used for 30 years without problems. The specific cleaning and maintenance methods are as follows:

During installation

1. The parts that need to be welded need to be painted with anti-rust paint after welding.

During use

1. Keep it clean at ordinary times and avoid being covered with all kinds of dirt, especially the residues of corrosive items.

2. If it is found that the galvanized layer is gone, apply anti-rust paint in time.

3. Steel gratings fixed with bolts must be inspected regularly to see if the bolts are loose and any hidden dangers must be dealt with in a timely manner.

Hot-dip galvanized steel grating must not only be maintained during use, but also pay attention when purchasing: the hot-dip galvanized zinc layer must be of good quality and there must not be a large number of missed coatings. The zinc layer should not be too thin (which will affect the anti-corrosion life) nor too thick (if it is too thick, the surface zinc layer will fall off).

Post time: Apr-16-2024