1. Steel grating classification:

There are more than 200 specifications and varieties of plane type, tooth type and I type (according to different use environments, different protective treatments can be carried out on the surface).

2. Steel grating material:

Q253 steel plate, stainless steel plate, twisted steel bar, stainless steel 304.316 material.

3. Processing method of steel grating:

There are two kinds of machine pressure welding and manual production: machine pressure welding uses a high-voltage resistance pressure welding machine, and the manipulator automatically places the crossbars on the evenly arranged flat steel and press-welds the crossbars into the flat steel bars through powerful electric welding power and hydraulic pressure. steel, so that the steel grating with strong welding spots, high stability, and strength can be obtained;

The artificial steel grating is punched on the flat steel first, and then the crossbar is put into the hole for spot welding. There will be gaps between the crossbar and the flat steel, but each contact point can be welded to achieve flat steel and twist. The equivalent melting connection of steel, so the welding will be stronger and the strength will be improved, but the appearance is not as beautiful as that of pressure welding!

Both methods have their own advantages and disadvantages, and the specific choice depends on the aspects that customers value more.

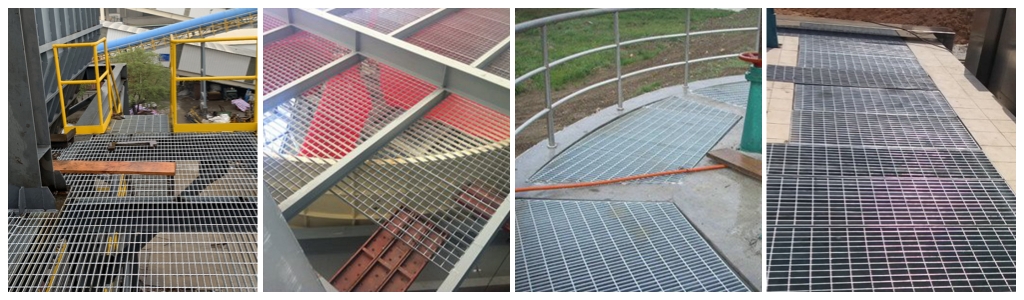

4. Advantages of steel grating:

Lightweight, high strength, large load-bearing capacity, economical material saving, ventilation and light transmission, modern style, beautiful appearance, non-slip, easy to clean, easy to install, and durable.

5. Application of steel grating:

Power plants, chemical plants, oil refineries, steel plants, machinery manufacturing plants, shipyards, paper mills, cement plants, food processing plants, bridge engineering, municipal engineering projects, etc. It is widely used in various factories and engineering projects.

CONTACT

Anna

Post time: Mar-27-2023