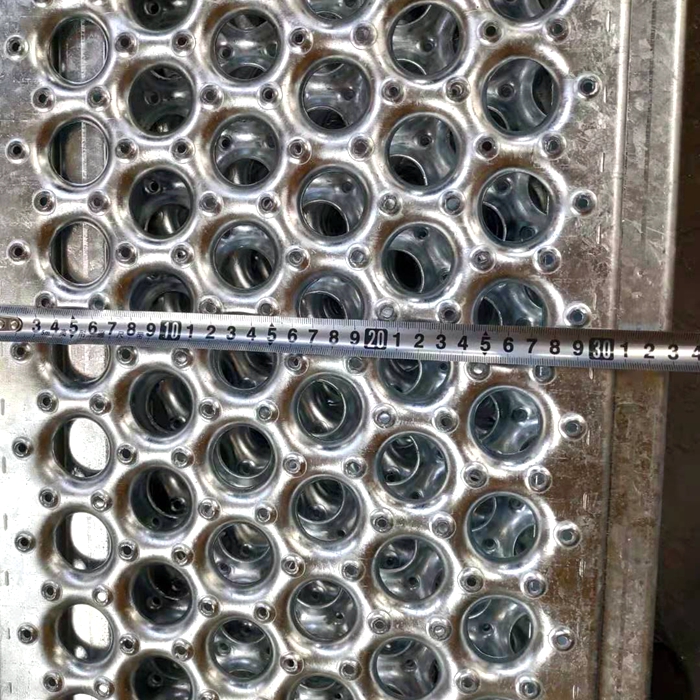

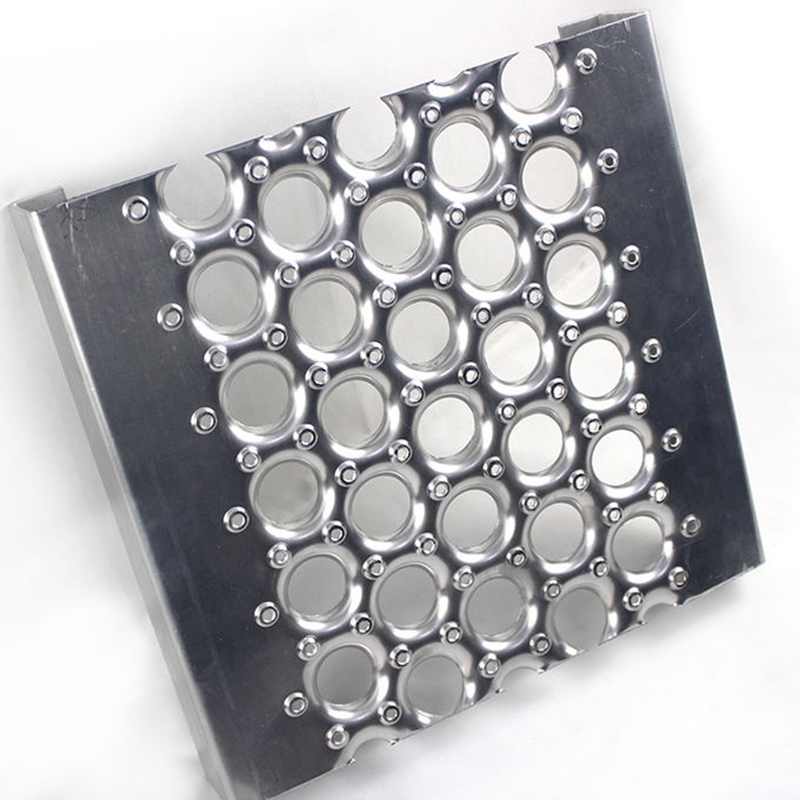

Non Skid Metal Plate Anti Slip Sheet Metal for Workshop

Non Skid Metal Plate Anti Slip Sheet Metal for Workshop

Features

The punched skid plate is made of high quality 304 stainless steel, which is waterproof, corrosion resistant and easier to clean.

The machine is specially designed, integrated, mechanized production, seamless welding process, uniform mesh, accurate size.

Good anti-slip performance, high bearing capacity, strong compression resistance, tough and firm.

Strong material, stable structure, strong impact resistance, no burr, durable.

The material can be iron plate, aluminum plate, stainless steel plate and so on. Plates of different materials can be selected according to different use environments, which are cheap, high-quality and durable.

The thickness is generally 1mm-5mm, and can be customized to any size according to customer requirements.

| Material | hot rolled, cold rolled, aluminum, galvanized plate,

stainless steel panel etc. |

| Hole patterns | crocodile mouth, round raised hole, tears shape etc. |

| Thickness | generally 2mm, 2.5mm, 3.0mm |

| Height | 20mm, 40mm, 45mm, 50mm, customized |

| Length | 1m, 2m, 2.5m, 3.0m, 3.66m |

| Production technique | punching, cutting, bending, welding |

| Use | Anti-skid plate can be widely used in sewage treatment, power plant,

snow, stair step, antiskid pedal, and many other anti-skid areas. |

Application

Because of its good skid resistance and aesthetics, it is widely used in industrial plants, production workshops, transportation facilities, etc. It is suitable for environments with mud, oil, rain, and snow, and can effectively play a role in safety and anti-slip.

FAQ

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

You can make the payment to our bank account, Western Union or PayPal:

30% deposit in advance, 70% balance against the copy of B/L.

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

CONTACT