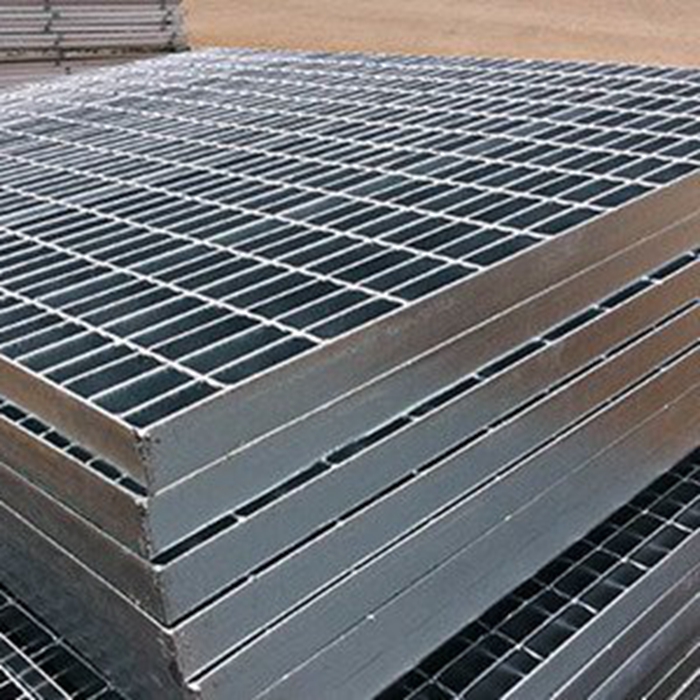

Galvanizing-kululku waa mid ka mid ah hababka muhiimka ah ee ka-hortagga daxalka ee inta badan loo isticmaalo daawaynta dusha sare ee shabagga birta. Deegaanka daxalka ah, dhumucda lakabka galvanized ee qashinka birta ayaa saameyn toos ah ku leh caabbinta daxalka. Marka la eego xaaladaha xoogga isku-xidhka ee isku midka ah, dhumucda dahaarka (qadarka adhesion) waa ka duwan yahay, iyo muddada iska caabinta daxalka ayaa sidoo kale ka duwan. Zinc waxay leedahay waxqabad aad u wanaagsan oo ah walxo ka hortag ah oo loogu talagalay saldhigga birta. Awoodda korantada ee zinc ayaa ka hooseysa tan birta. Joogitaanka elektrolytka, zinc wuxuu noqdaa anode wuxuuna lumiyaa electrons wuxuuna si doorbidaa u daxaliyaa, halka saldhigga birta ee birta ay noqoto cathode. Waxaa laga ilaaliyaa daxalka ilaalinta korantada ee lakabka galvanized. Sida iska cad, dahaarka khafiifka ah, gaaban muddada caabbinta daxalka, iyo muddada caabbinta daxalka kordho marka dhumucdiisuna dahaarka korodho. Si kastaba ha ahaatee, haddii dhumucda dahaarka ay aad u qaro weyn tahay, xoogga isku xidhka ee u dhexeeya daahan iyo substrate birta ayaa si aad ah hoos ugu dhici doona, taas oo yareyn doonta muddada caabbinta daxalka mana aha mid dhaqaale ahaan kharash-ool ah. Sidaa darteed, waxaa jira qiimo ugu fiican ee dhumucda dahaarka, mana fiicna inaad aad u dhumucdo. Falanqaynta ka dib, ee kululaynta galvanized birta daajinta qaybo ka mid ah qeexitaanno kala duwan, dhumucdiisuna daahan ugu fiicnayn ayaa ugu habboon in la gaaro muddada ugu dheer ee iska caabinta daxalka.

Siyaabaha lagu hagaajiyo dhumucda daahan

1. Dooro heerkulka ugu fiican ee galvanizing

Sida loo xakameeyo heerkulka galvanizing ee shafka birta ayaa aad muhiim u ah si loo hubiyo loona hagaajiyo tayada daahan. Sannado badan oo ku saabsan dhaqanka wax soo saarka ka dib, waxaan aaminsanahay inay ku habboon tahay in la xakameeyo heerkulka galvanizing kulul ee 470 ~ 480 ℃. Marka dhumucda qaybta dhejiska ah ay tahay 5mm, dhumucda dahaarka waa 90 ~ 95um (heerkulka deegaanka waa 21 ~ 25 () Waqtigaan, shabaqyada kuleylka kuleylka leh ee galvanized waxaa lagu tijaabiyaa habka sulfate copper. Natiijooyinku waxay muujinayaan in: dahaarka waxaa lagu rusheeyaa wax ka badan 7 jeer iyada oo aan soo bandhigin matrixka birta ah; Marka heerkulka immersion Zinc waa 455 ~ 460 ℃, dhumucdiisuna daahan ayaa dhaaftay qiimaha ugu fiican Waqtigan, inkastoo natiijada imtixaanka labis ah daahan waa wanaagsan (sida caadiga ah immersion in ka badan 8 jeer iyada oo aan soo bandhigin matrix ah), ay sabab u tahay kororka ee viscosity dareere zinc, ifafaale sagging waa ka sii cad, marka imtixaan la isku dayayo in ay dhacdo 510 ~ 520 ℃, dhumucdiisuna waxay ka yar tahay qiimaha ugu fiican (sida caadiga ah ka yar 60um).

2. Xakamee xawaaraha qaadista ee qaybaha dahaadhka ah. Xawaaraha qaadista qaybaha dahaadhka birta ee dareeraha zinc waxay saameyn muhiim ah ku leedahay dhumucda dahaarka. Marka xawaaraha qaadista uu yahay mid degdeg ah, ka dibna lakabka galvanized waa qaro weyn. Haddii xawaaraha qaadistu uu gaabis yahay, dahaarka ayaa noqon doona mid khafiif ah. Sidaa darteed, xawaaraha qaadista waa inuu ahaadaa mid ku habboon. Haddii ay aad u gaabis tahay, lakabka daawaynta birta-zinc iyo lakabka zinc saafiga ah ayaa fidi doona inta lagu guda jiro habka kor u qaadida ee qaybaha birta ah ee dahaadhka ah, si lakabka zinc saafiga ah uu si buuxda u beddelo lakabka alloy, waxaana la sameeyay filim cawl-haraad ah, kaas oo yareynaya waxqabadka foorarsiga ee daahan. Intaa waxaa dheer, marka lagu daro in lala xiriiriyo xawaaraha kor u qaadista, waxay sidoo kale si dhow ula xiriirtaa xagasha qaadista.

3. Si adag u xakamee wakhtiga immersion zinc

Waxaa si fiican loo og yahay in dhumucda dahaarka shabagga birta ay si toos ah ula xiriirto waqtiga immersion zinc. Wakhtiga immersion zinc inta badan waxaa ka mid ah wakhtiga loo baahan yahay in meesha laga saaro gargaarka dahaadhka ee dusha sare ee qaybaha dahaadhka ah iyo wakhtiga loo baahan yahay in la kululeeyo qaybaha dahaadhan heerkulka dareeraha zinc iyo ka saar ash zinc ee dusha dareeraha ka dib zinc immersion. Xaaladaha caadiga ah, wakhtiga zinc immersion ee qaybaha dhejiska ah waxaa la xakameynayaa wadarta wakhtiga marka falcelinta u dhaxaysa qaybaha taajaysan iyo dareeraha zinc la joojiyo oo laga saaro dambaska zinc ee dusha dareeraha ah. Haddii wakhtigu aad u gaaban yahay, tayada qaybaha birta lagu dhejiyay lama dammaanad qaadi karo. Haddii wakhtigu aad u dheer yahay, dhumucda iyo jajabnaanta daboolka ayaa kordhi doona, iyo iska caabbinta daxalka ee dahaarka ayaa hoos u dhigi doona, taas oo saameyn doonta nolosha adeegga ee qaybaha qashinka birta ah.

Waqtiga boostada: Juun-20-2024