Hangata e le ho matlafatsa lerako, ba bangata ba sebelisa mesh e matlafatsang e kopantsoeng le konkreite leboteng ho finyella phello e ntle ea ho matlafatsa. Ka tsela ena, lerako lohle le ka matlafatsoa khahlanong le ho kobeha le ho hanyetsa litšisinyeho tsa lefatše, tse ka ntlafatsang haholo matla a ho jara maralo a matlafalitsoeng le ho thibela ho hlaha ha mapetsong. Ka mor'a ho sebelisa litšiea tsa konkreite tse matlafalitsoeng, matla a ho beha lebota, tšebeliso ea matla le ductility coefficient e ntlafalitsoe, hape e na le khanyetso ea tšisinyeho ea lefatše, ho hanyetsa ho phatloha le thepa e khahlanong le ho oa.

Ka thuso ea melemo le litšoaneleho tsena tsa ho matlafatsa mesh, haeba mesh ea tšepe e behiloe leboteng la mohaho, ho phunyeha ha lerako ho tla fokotseha ka tsela e nepahetseng, 'me ts'ebetso ea seismic e ka boela ea ntlafatsoa. Ka hona, mesh ea tšepe e bohlokoa haholo mererong ea kaho. Lisebelisoa tse fokolang tsa mohaho.

Ho matlafatsa letlooeng ho ka matlafatsa botsitso ba eona le ho hanyetsa kutu ka ho roala ho batang (electroplating), dip e chesang, le ho roala ha PVC holim'a lisebelisoa tse tala (tšepe ea boleng bo tlaase ba carbon steel kapa rebar), hammoho le gridi e ts'oanang le lintlha tse matla tsa welding, ts'ebetso e ntle ea sebakeng seo, e le hore mesh ea tšepe e leboteng le ka ntle la mohaho e ka fana ka tšebeliso e ntle ea ho itšehla thajana le ho sireletsa marako.

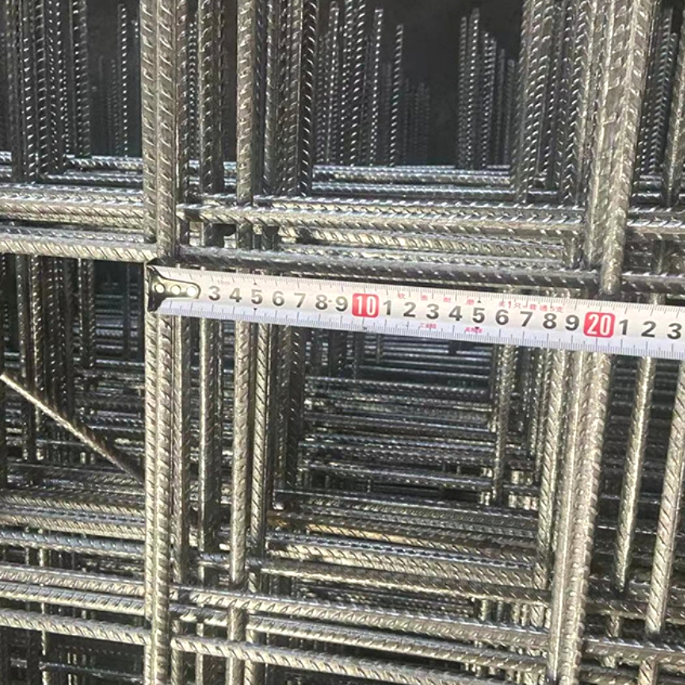

Thepa ea mochini ea ho tiisa letlooeng ha e na phetoho e ka bang teng pele le ka mor'a welding. Melemo ea ho matlafatsa letlooeng ke lebelo la ho theha ka potlako, boleng bo tsitsitseng, sebaka se lekanang pakeng tsa litšepe tse tšekaletseng le tse theohileng, le likhokahano tse matla mateanong a litsela. Ho lokela ho hlokomeloa hore sebaka le bophara ba mekoallo ea tšepe ka litsela tse otlolohileng le tse rapameng li ka fapana, empa mekoallo ea tšepe ka lehlakoreng le le leng e lokela ho ba le bophara bo lekanang, sebaka le bolelele.

Mesh e matlafatsang welding e phetha karolo ea bohlokoa boleng ba morero oa ho matlafatsa, lebelo la kaho le lona le ntlafatsoa, 'me ho hanyetsa mapheo a konkreite hoa ntlafatsoa. Reinforcing mesh e na le litšobotsi tse felletseng tsa ts'ebetso e phahameng le ho boloka matla. Ke thepa e ncha ea moaho e sebelisetsoang ho tiisa meaho ea konkreite 'me e na le melemo e metle haholo ea moruo. E 'nile ea sebelisoa haholo indastering ea kaho ea morao-rao' me e nkile sebaka sa mokhoa o fetileng oa matsoho oa ho tlama litšepe setšeng.

Melemo e ikhethang ka ho fetesisa ea ho matlafatsa mesh ke ho cheseha ha eona ho matla, ho hanyetsa kutu, ho hanyetsa oxidation le khatello e matla ea khatello. Nolofatsa bongata ba morero le ho khutsufatsa nako ea kaho. Ka kakaretso, 33% ea tšepe e ka bolokeha nakong ea kaho, litšenyehelo li ka fokotsoa ka 30%, 'me katleho ea kaho e ka eketseha ka 75%.

Ha e potlakise kaho feela, empa hape e tiisa tšireletseho. Bothata ba tšilafalo ea lerata bo hlahisitsoeng nakong ea ts'ebetso ea kaho ea morero bo se bo rarollotsoe hape, 'me bo khothalletsa kaho e tsoetseng pele setšeng.

Ho matlafatsa marang-rang ho sebelisoa litsing tsa 'masepala: paving ea viaduct, liphaephe tsa konkreite, marako, tšireletso ea letsoapo, joalo-joalo; polokelo ea metsi le lisebelisoa tsa matla a motlakase: lisebelisoa tsa ho boloka metsi, metheo ea matamo, matlooa a sireletsang, joalo-joalo Mesh e matlafalitsoeng e boetse e sebelisoa libakeng tse ling: lisebelisoa tsa ho laola likhohola, matlafatso ea matsoapo, tšireletso ea ho thibela ho putlama, temo ea metsing, leruo la liphoofolo, joalo-joalo.

Nako ea poso: Jan-18-2024