Ngexesha lenkqubo yokuvelisa imigodi yamalahle, umthamo omkhulu wamanzi aphantsi komhlaba uya kuveliswa. Amanzi aphantsi komhlaba aphumela kwitanki yamanzi ngomsele obekwe kwelinye icala letonela, aze akhutshelwe emhlabeni ngempompo enezigaba ezininzi. Ngenxa yokunqongophala kwesithuba somjelo ongaphantsi komhlaba, isigqubuthelo sidla ngokudityaniswa ngaphezu komsele njengendlela esecaleni ukuze abantu bahambe kuwo.

Izigqubuthelo zomsele ezidla ngokusetyenziswa eTshayina ngoku ziimveliso zesamente. Olu hlobo lwesigqubuthelo luneziphene ezicacileyo ezifana nokuqhekeka lula, okubeka ingozi enkulu kwimveliso ekhuselekileyo yemigodi yamalahle. Ngenxa yempembelelo yoxinzelelo lwasemhlabeni, umsele kunye nokugubungela umsele zihlala ziphantsi koxinzelelo olukhulu. Ngenxa yokuba isigqubuthelo se-samente sineplastiki ehluphekileyo kwaye akukho mandla okuguqula iplastiki, idla ngokuphuka kwaye ilahlekelwe ngumsebenzi wayo ngokukhawuleza xa iphantsi koxinzelelo lomhlaba, ibeka ingozi enkulu ekukhuselekeni kwabantu abahamba kuyo kunye nokulahlekelwa ukukwazi ukusetyenziswa kwakhona. Ngoko ke, kufuneka itshintshwe rhoqo, ixabiso lokusetyenziswa liphezulu, kwaye libeka uxinzelelo kwimveliso yemigodi. Isigqubuthelo sesamente sinzima kwaye sinzima kakhulu ukuhlohla nokubuyisela xa sonakalisiwe, nto leyo eyandisa umthwalo kubasebenzi kwaye ibangele inkcitho enkulu yabasebenzi kunye nezixhobo eziphathekayo. Ngenxa yokuba isigqubuthelo sesamente esaphukileyo siwela emhadini, umsele kufuneka ucocwe rhoqo.

Uphuhliso lokuvala umsele

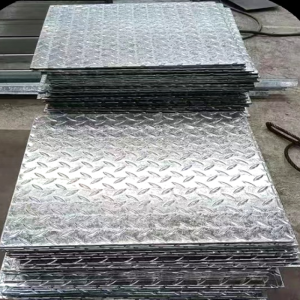

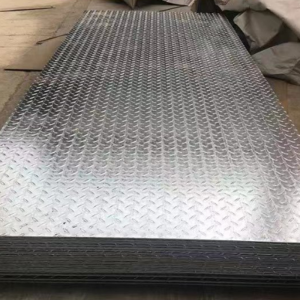

Ukoyisa iziphene zokhuselo lwesamente, qinisekisa ukhuseleko lokuhamba kwabasebenzi, kuncitshiswe iindleko zemveliso, kunye nabasebenzi abakhululekileyo kwimisebenzi enzima yomzimba, umzi-mveliso wokulungisa umatshini wamalahle waququzelela amagcisa ukuyila uhlobo olutsha lokuvala umsele olusekelwe kuqheliselo oluninzi. Isigqubuthelo somsele esitsha senziwe ngepleyiti yentsimbi engqindilili eyi-5mm emile okwelentile. Ukuze ukwandise amandla ekhava, i-rib yokuqinisa inikezelwa phantsi kwekhava. I-rib yokuqinisa yenziwe nge-30x30x3mm yentsimbi ye-equilateral angle, edityaniswe ngokukhawuleza kwi-plate yensimbi enepateni. Emva kwe-welding, i-cover ifakwe i-galvanized iyonke ukwenzela ukukhusela i-rust kunye ne-corrosion. Ngenxa yobukhulu obahlukeneyo bemijelo engaphantsi komhlaba, ubungakanani obukhethekileyo bokusetyenzwa kwesigqubuthelo somsele kufuneka bucutshungulwe ngokobukhulu bokwenene bomsele.

Uvavanyo lwamandla lokuvala umsele

Ekubeni isigqubuthelo somsele sidlala indima yendlela yabahambi ngeenyawo, kufuneka sikwazi ukuthwala umthwalo owaneleyo kwaye sibe nokhuseleko olwaneleyo. Ububanzi bokhuselo lomsele bumalunga ne-600mm, kwaye inokuthwala umntu omnye xa uhamba. Ukuze ukwandise ukhuseleko, sibeka into enzima ngamaxesha e-3 ubukhulu bomzimba womntu kwi-cover cover xa usenza iimvavanyo ezimileyo. Uvavanyo lubonisa ukuba isigqubuthelo siqhelekile ngokupheleleyo ngaphandle kokugoba okanye ukugoba, nto leyo ebonisa ukuba amandla okhuselo olutsha asebenza ngokupheleleyo kwipaseji yabahambi ngeenyawo.

Izinto eziluncedo zokuvala umsele

1. Ubunzima bokukhanya kunye nokufakwa lula

Ngokwezibalo, isigqubuthelo esitsha somsele sinobunzima obumalunga ne-20ka, esimalunga nesiqingatha sesigqubuthelo sesamente. Ilula kwaye kulula kakhulu ukuyifaka. 2. Ukhuseleko olulungileyo kunye nokuqina. Ekubeni isigqubuthelo esitsha somsele senziwe ngeplate yensimbi enepateni, ayinamandla nje kuphela, kodwa nayo ayiyi konakala ngokuphuka kwe-brittle kwaye iqinile.

3. Inokusetyenziswa kwakhona

Ekubeni isigqubuthelo somsele esitsha senziwe ngeplate yensimbi, inomthamo othile wokuguqulwa kweplastiki kwaye ayiyi konakala ngexesha lokuthutha. Nokuba kwenzeka i-deformation yeplastiki, ingaphinda isetyenziswe emva kokuba i-deformation ibuyiselwe. Ngenxa yokuba isigqubuthelo somsele omtsha sinezi nzuzo zingentla, siye sakhuthazwa ngokubanzi saza sasetyenziswa kwimigodi yamalahle. Ngokutsho kweenkcukacha-manani zokusetyenziswa kwezigqubuthelo zomsele omtsha kwimigodi yamalahle, ukusetyenziswa kwezigqubuthelo ezintsha zomsele kuphucule kakhulu ukuveliswa, ukufakwa, iindleko kunye nokhuseleko, kwaye kufanelekile ukukhuthazwa kunye nokusetyenziswa.

Ixesha lokuposa: Jun-12-2024