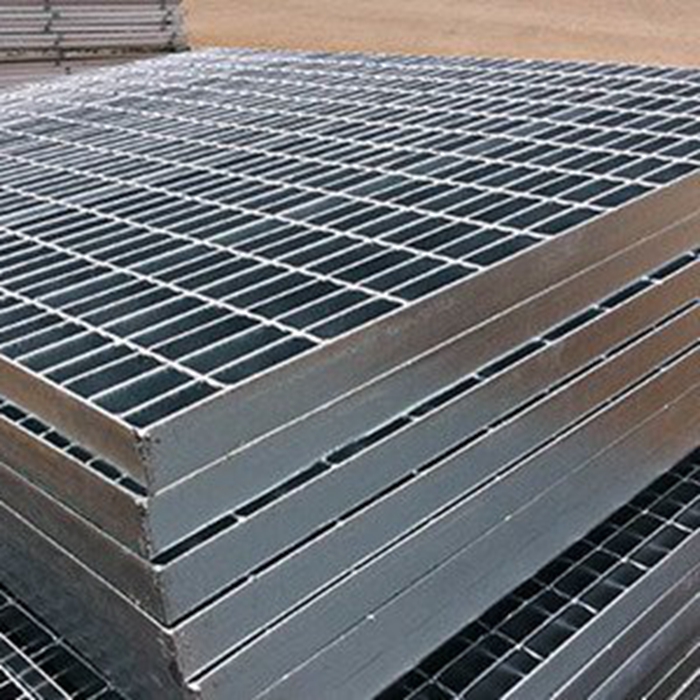

I-Hot-dip galvanizing yenye yeendlela ezibalulekileyo zokunqanda ukubola ezisetyenziswa ngokuqhelekileyo kunyango lomphezulu wegrayiti yentsimbi. Kwindawo engcolileyo, ubukhulu bomgca we-galvanized we-grating yensimbi inefuthe elithe ngqo kwi-corrosion resistance. Ngaphantsi kweemeko zamandla okubambisana okufanayo, ubukhulu bengubo (ixabiso lokunamathela) lihluke, kwaye ixesha lokumelana nokubola likwahlukile. I-Zinc inentsebenzo egqwesileyo ngokugqithisileyo njengesixhobo sokukhusela isiseko sentsimbi yentsimbi. Amandla e-electrode ye-zinc angaphantsi kuneyentsimbi. Phambi kwe-electrolyte, i-zinc iba yi-anode kwaye ilahlekelwa yi-electron kunye ne-corrodes ngokukhethiweyo, ngelixa isiseko se-steel grating siba yi-cathode. Ikhuselwe kwi-corrosion ngokukhuselwa kwe-electrochemical ye-galvanized layer. Ngokucacileyo, ukuncipha kwengubo, ixesha elifutshane lokuxhathisa umhlwa, kunye nexesha lokumelana nokukhula linyuka njengoko ubukhulu bengubo busanda. Nangona kunjalo, ukuba ubuninzi be-coating bukhulu kakhulu, amandla okudibanisa phakathi kwengubo kunye ne-metal substrate iya kuhla ngokukhawuleza, okuya kunciphisa ixesha lokumelana nokubola kwaye akubizi kakhulu ngokwezoqoqosho. Ke ngoko, kukho ixabiso elilelona lifanelekileyo lobunzima bokugquma, kwaye akulunganga ukutyeba kakhulu. Emva kokuhlalutya, kwintsimbi eshushu-yediphu yentsimbi yokugalela iinxalenye zeenkcukacha ezahlukeneyo, eyona nto ifanelekileyo yokwaleka ukufezekisa elona xesha lide lokuxhathisa umhlwa.

Iindlela zokuphucula ubukhulu bengubo

1. Khetha elona qondo lobushushu le-galvanizing

Indlela yokulawula ukushisa kwe-galvanizing ye-steel grating ibaluleke kakhulu ukuqinisekisa nokuphucula umgangatho wokugquma. Emva kweminyaka yokuziqhelanisa nemveliso, sikholelwa ukuba kufanelekile ukulawula iqondo lobushushu lediphu yokuntywila kwi-470 ~ 480℃. Xa ubukhulu becala elicwengekileyo liyi-5mm, ubukhulu bokugquma buyi-90 ~ 95um (ubushushu be-ambient yi-21 ~ 25 () Ngeli xesha, i-hot-dip galvanized grating ivavanywa ngendlela ye-copper sulfate. Iziphumo zibonisa ukuba: ukugubungela kuntywiliselwa amaxesha angaphezu kwe-7 ngaphandle kokutyhila i-iron matrix engaphezulu (i-9) ngaphandle kwe-iron matrix (i-9) ibe yintsimbi ye-iron. Xa iqondo lobushushu le-zinc liyi-455 ~ 460 ℃, ubukhulu bokugquma bugqithile kwixabiso elifanelekileyo Ngeli xesha, nangona iziphumo zovavanyo zokwaleka zilungile (zidla ngokuntywiliselwa ngaphezulu kwamaxesha esi-8 ngaphandle kokuvezwa kwe-matrix), ngenxa yokwanda kwe-zinc ye-viscosity yolwelo, ukugoba okubonakalayo, ukugoba okubonakalayo akubonakali. Xa iqondo lobushushu le-zinc liyi-510 ~ 520 ℃, ubukhulu be-coating bungaphantsi kwexabiso elifanelekileyo (ngokuqhelekileyo lingaphantsi kwe-60um) inani eliphezulu lemilinganiselo yokulinganisa i-4 yokutyhila i-matrix, kwaye ukuxhathisa ukubola akuqinisekiswanga.

2. Lawula isantya sokunyuswa kweendawo ezicwengiweyo. Isantya sokuphakamisa i-steel grating plated parts from the zinc liquid inefuthe elibalulekileyo kwi-coating thickness. Xa isantya sokuphakamisa sikhawuleza, ngoko ke I-galvanized layer inzima. Ukuba isantya sokuphakamisa sicotha, isambatho siya kuba sincinci. Ngoko ke, isantya sokuphakamisa kufuneka sifaneleke. Ukuba icotha kakhulu, umaleko we-iron-zinc ialloy kunye ne-zinc ecocekileyo iya kusasazeka ngexesha lokunyuswa kweentsimbi ze-grating, ukwenzela ukuba umaleko we-zinc ococekileyo uguqulwe ngokupheleleyo ube ngumaleko we-alloy, kunye nefilimu enxaniweyo engwevu, enciphisa ukusebenza kokugoba kwengubo. Ukongezelela, ngaphezu kokuhambelana nesantya sokunyusa, kukwahambelana ngokusondeleyo kwi-angle yokuphakamisa.

3. Lawula ngokungqongqo ixesha lokuntywiliselwa kwe-zinc

Kuyaziwa kakuhle ukuba ubukhulu bentsimbi yentsimbi yentsimbi buhambelana ngokuthe ngqo nexesha lokucwiliswa kwe-zinc. Ixesha lokuntywiliselwa i-zinc ikakhulu libandakanya ixesha elifunekayo lokususa uncedo lokucwenga kumphezulu weendawo ezicandiweyo kunye nexesha elifunekayo ukufudumeza iindawo ezicandiweyo kwiqondo lobushushu lolwelo lwe-zinc kunye nokususa umlotha we-zinc kumphezulu wolwelo emva kokuntywiliselwa kwe-zinc. Ngaphantsi kweemeko eziqhelekileyo, ixesha lokucwiliswa kwe-zinc lamacandelo adibeneyo lilawulwa kwi-sum of the sum of the reaction between the plated parts and the zinc liquid isemed and the zinc ash on the liquid surface is kususwa. Ukuba ixesha lifutshane kakhulu, umgangatho we-steel grating plated parts awukwazi ukuqinisekiswa. Ukuba ixesha lide kakhulu, ubukhulu kunye ne-brittleness ye-coating iya kwanda, kwaye ukunyanzeliswa kwe-corrosion ye-coating kuya kuncipha, okuya kuchaphazela ubomi benkonzo ye-steel grating plated parts.

Ixesha lokuposa: Jun-20-2024