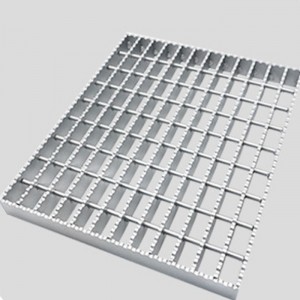

Ngophuhliso olukhawulezayo lwethekhnoloji yoshishino, ukusetyenziswa kwegridi yensimbi enezinyo kuya kuba kuninzi ngakumbi, kwaye imfuno iyanda. Intsimbi ethe tyaba enamazinyo ikholisa ukwakhelwa kwigrayiti yentsimbi enamazinyo, esetyenziswa kwiindawo ezigudileyo nezimanzi kunye namaqonga e-oyile aphesheya konxweme. Ukongeza kwiimpawu zentsimbi yentsimbi eqhelekileyo, i-toothed steel gratings nayo inamandla okulwa ne-slip. Isigqubuthelo somsele esakhiwe ngokusetyenziswa sidibaniswe nesakhelo esineehenjisi, esinenzuzo yokhuseleko, ukulwa nobusela kunye nokuvulwa okufanelekileyo.

Izinto ezisetyenziselwa ukusetyenzwa kwentsimbi enamazinyo athambileyo yintsimbi yekhabhoni ephezulu, eyenza ukomelela kunye nokuqina kwentsimbi yentsimbi ibe phezulu kakhulu kuneepleyiti zentsimbi zemveli. Ingasetyenziswa kwiindawo ezinkulu kunye neendawo ezinomthwalo onzima ezifana needokhi kunye nezikhululo zeenqwelo moya. Ukongeza, i-toothed steel grating nayo ineenzuzo ze-mesh enkulu, i-drainage elungileyo, inkangeleko entle, kunye nokonga utyalo-mali. Ummandla wokuvuza ungaphezu kokuphindwe kabini kwentsimbi yentsimbi, efikelela kwi-83.3%, enemigca elula, imbonakalo yesilivere, kunye neengcamango ezinamandla zanamhlanje. Ubume bensimbi ene-toothed flat isiqingatha senyanga sisasazwa ngokulinganayo kwicala elinye. Ubungakanani obuthile kunye nesithuba sesiqingatha senyanga sinokuyilwa ngokweemfuno zangempela. Inkangeleko ilula kwaye ifanelekile kwi-die punching kunye nokusika. Okwangoku, eyona ndlela iphambili yokucubungula intsimbi ene-toothed flat kukubumba okutshisayo, okuneengxaki ezinkulu, ezifana nokusebenza okuphantsi, ukusetyenziswa kwamandla aphezulu kunye nokuchaneka kweprofayili yezinyo eliphantsi. Nangona ezinye izixhobo zasekhaya ukusetyenzwa kwamazinyo flat intsimbi lulawulo semi-automatic, ukondla yayo, ngenqindi kunye blanking kufuna ukusebenza ngesandla, kwaye ukuchaneka akukho phezulu. Ukusebenza kwemveliso yenyanga kuphantsi kwaye akukwazi ukuhlangabezana neemfuno zemarike. Umatshini wokubethelwa wentsimbi othe tyaba onamazinyo aphezulu luhlobo olutsha lwezixhobo ezisebenzisa indlela yokugqobhoza ukuze kusetyenzwe ngentsimbi enamazinyo. Iqaphela i-automation epheleleyo ukusuka ekutyiseni, ukubethelwa ukuya ekukhanyeni. Ukusebenza kakuhle kunye nokuchaneka kokucubungula ngamaxesha angama-3-5 eendlela zokucubungula zendabuko, kwaye ikwasindisa abasebenzi kwaye ifikelela kwinqanaba eliphambili lasekhaya.

Ulwakhiwo lulonke: Iskimu esipheleleyo somatshini wokubethelwa kwentsimbi yentsimbi ye-CNC enamazinyo abonakaliswe kumzobo. Isakhiwo esipheleleyo somatshini wokubhobhoza ngokuyinhloko sahlulwe kwindlela yokutya ngamanyathelo, isixhobo sokutya sangaphambili, isixhobo sokutya ngasemva, isixhobo sokubhoboza, isixhobo esihambelanayo se-hydraulic, i-die, i-bearing material, inkqubo ye-pneumatic kunye nenkqubo ye-CNC. Isixhobo sokubhoboza sensimbi ene-toothed sinqunywe ngokwenkqubo yokuvelisa isinyithi esicaba. Ububanzi bentsimbi yesicaba kwimveliso yangempela kunye nokucubungula ngokubanzi yi-25 ~ 50mm. Izinto eziphathekayo zentsimbi yentsimbi yi-Q235. Intsimbi enezinyo esicaba yenziwe ngesangqa esinecala elinye ngokumila kwamazinyo. Ukubonakala kunye nesakhiwo silula kwaye sifanelekile kakhulu ukubethelwa kunye nokwenza.

Umatshini we-CNC onamazinyo we-flat punching wensimbi wamkela inkqubo ye-S7-214PLC CNC ukufezekisa ukusika ngokukhawuleza naphakathi. Kwimeko yokungaphumeleli okanye i-jamming, iya kwenza i-alamu ngokuzenzekelayo kwaye iyeke. Ngokusebenzisa umboniso we-TD200 wombhalo, iiparitha ezahlukeneyo kwinkqubo yokubhoboza zinokusetwa ngokwahlukileyo, kubandakanywa umgama ngamnye wentsimbi yesicaba, isantya sokuhamba, inani leengcambu zokubetha, njl.

Iimpawu zokusebenza

(1) Isakhiwo esipheleleyo somatshini wokubhobhoza siyilwe, kubandakanywa isixhobo sokutya, isixhobo sokubetha, inkqubo ye-hydraulic, kunye nenkqubo ye-CNC.

(2) Isixhobo sokutyisa samkela i-encoder evaliweyo-loop impendulo indlela yokuqhuba intsimbi ecaba ngobude obuchaziweyo.

(3) Isixhobo sokubhoboza sisebenzisa i-conjugate cam punching indlela yokubetha ngokukhawuleza intsimbi ecaba.

(4) Inkqubo ye-hydraulic kunye nenkqubo ye-CNC ehambelana nomatshini wokubhoboza inyusa inqanaba lokuzenzekelayo lokubetha

(5) Emva kokusebenza kwangempela, ukuchaneka kwe-punching yomatshini wokubhoboza kunokuqinisekiswa ukuba yi-1.7± 0.2mm, ukuchaneka kwenkqubo yokutya kunokufikelela kwi-600 ± 0.3mm, kwaye isantya sokubetha singafikelela kwi-24 ~ 30m: min.

Ixesha lokuposa: Jun-14-2024