Izinkundla zokusebenza zendabuko zonke zibekwe ngamapuleti ensimbi anephethini emishayweni yensimbi. Amapulatifomu okusebenza embonini yamakhemikhali avame ukubekwa endaweni evulekile, futhi indawo yokukhiqiza yemboni yamakhemikhali igqwala kakhulu, okwenza kube lula ukuthi amandla nokuqina kube buthaka ngokushesha ngenxa yokugqwala, futhi impilo yesevisi iyancipha kakhulu. Ngesikhathi esifanayo, ama-welds amancane nawo athambekele ekulahlekelweni amandla, angabangela kalula izingozi zokuphepha. Amapuleti ensimbi anephethini adinga ukugqwala futhi adwetshwe esizeni, okudinga umsebenzi omkhulu futhi ikhwalithi yokwakha akulula ukuqinisekiswa; amapuleti ensimbi anephethini athambekele ekuwohlokeni nasekucindezelekeni, okubangela ukunqwabelana kwamanzi nokugqwala, futhi ukugcinwa okuphelele kokulwa nokugqwala kuyadingeka njalo eminyakeni emithathu ukuze kuqinisekiswe ukusebenza kwawo. Imboni yokukhiqiza amakhemikhali, enezidingo eziqinile zokulawula izinto ezivuthayo neziqhumayo, iletha iziphazamiso eziningi futhi ithinte ngisho nokukhiqizwa kwansuku zonke.

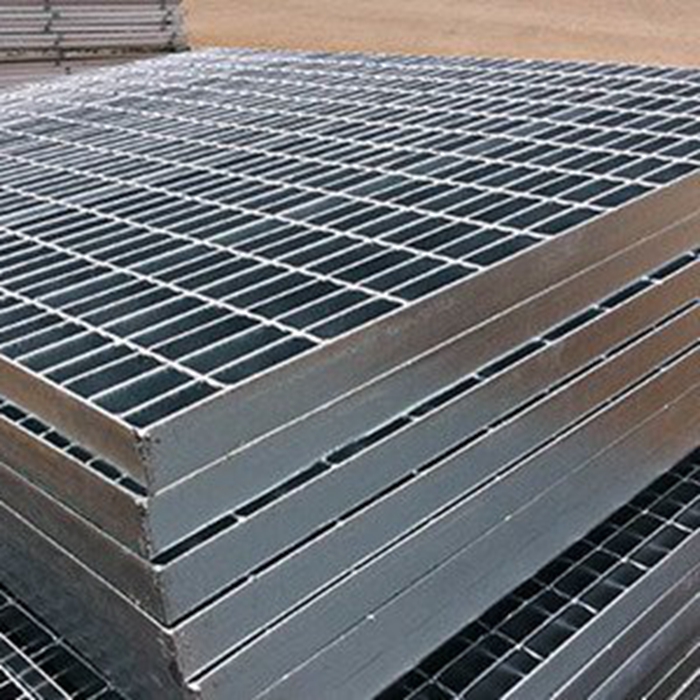

Eminyakeni yamuva, izinsimbi zensimbi zinganciphisa futhi zixazulule le nkinga ngezinga elikhulu. Ukusetshenziswa kwezigaxa zensimbi ezisekelweni zokusebenza zamayunithi e-petrochemical kunezinzuzo ezisobala kanye nethemba elibanzi kakhulu lesicelo. Igridi yensimbi, eyaziwa nangokuthi ipuleti legridi yensimbi, iwuhlobo lomkhiqizo wensimbi onamagridi ayisikwele phakathi, owenziwe ngensimbi eyisicaba ehlelwe ngesikhala esithile kanye nemigoqo ephambanayo, futhi ishiselwe noma ikhiywe ngokucindezela. Isetshenziselwa ikakhulukazi izembozo zomsele, amapuleti esiteji sesakhiwo sensimbi, kanye nokunyathela kwezitebhisi zensimbi. Ingasetshenziswa futhi njengama-filter gratings, ama-trestles, i-ventilation fences, iminyango namafasitela aphikisana nokweba, i-scaffolding, i-scaffolding, uthango lokuphepha kwemishini, njll. Inomoya, ukukhanya, ukuchithwa kokushisa, i-anti-slip, i-explosion-proof nezinye izakhiwo.

Ngenxa yokuba khona kwesikhala phakathi kwensimbi eyisicaba ye-steel grating plate, izinhlansi ezikhiqizwe ngesikhathi somsebenzi oshisayo azikwazi ukuvinjelwa. Ngokombono wegridi yensimbi esetshenziswayo njengamanje, igebe phakathi kwezinsimbi eziyisicaba likhulu kuno-15mm. Uma igebe lingu-15mm, amantongomane angaphansi kwe-M24, amabhawodi angaphansi kwe-M8, insimbi eyindilinga engaphansi kuka-15 kanye nezinduku zokushisela, kuhlanganise nezikrufu, zingase ziwe; uma igebe lingu-36mm, amantongomane angaphansi kwe-M48, amabhawodi angaphansi kwe-M20, insimbi eyindilinga engaphansi kuka-36 nezinduku zokushisela, kuhlanganise nezikrufu, zingase ziwe. Izinto ezincane eziwayo zingalimaza abantu ngezansi, kubangele ukulimala komuntu siqu; amathuluzi, izintambo zekhebula, amapayipi epulasitiki, izikali zezinga lengilazi, izibuko ezibonayo, njll. ocingweni zingalimala, kubangele izingozi ezibangelwa ukuhlotshaniswa kwemishini yokukhiqiza nokuvuza kwempahla. Ngenxa yokuba khona kwesikhala samagridi ensimbi, amanzi emvula awakwazi ukuvinjelwa, futhi izinto ezivuzayo ukusuka esitezi esiphezulu ziconsela esitezi sokuqala, okwandisa ukulimala kubantu abangaphansi.

Nakuba ama-grating ensimbi anezinzuzo eziningi ngaphezu kwamapuleti ensimbi anephethini yendabuko, njengomnotho nokuphepha, kanye nenani eliphezulu lokusebenza-intengo, amamodeli afanelekayo e-steel grating kufanele akhethwe ngangokunokwenzeka ngesikhathi sokuklama nokukhethwa, kodwa ekusetshenzisweni kwangempela, izinsimbi zensimbi zingahlanganiswa namapuleti ensimbi anephethini ukuze kuhlangatshezwane nezidingo zesakhiwo ezinengqondo, izidingo zokukhiqiza kanye nokuzuza izinzuzo zezomnotho ezicacile.

Ngokusho kwalesi simo esingenhla, lezi zimiso ezilandelayo kufanele zilandelwe lapho kusetshenziswa amapuleti ensimbi anephethini kanye nama-gratings ensimbi phansi kwesakhiwo sensimbi. Uma uhlaka lwedivayisi luyisakhiwo sensimbi, ama-grating ensimbi akhethwa phansi kanye nezitebhisi. Amapuleti ensimbi anephethini akhethwa ekwakheni amaphasishi, ikakhulukazi ukuze kube lula ukudlula kwabantu abane-acrophobia. Uma okokusebenza namapayipi kugcwele kuhlaka, kufanele kusetshenziswe amapuleti ensimbi anephethini aphansi, ikakhulukazi ngenxa yokuthi amagridi ensimbi akulula ukuthi acutshungulwe abe ama-arcs. Ngaphandle kokuthi zenziwe ngokwezifiso, kuzothinta amandla onke ama-gratings ensimbi. Lapho ukuvimbela amanzi kudingekile phakathi kwaphansi, kufanele kusetshenziswe amapuleti ensimbi anephethini phansi, okungenani indawo engaphezulu kufanele ibe amapuleti ensimbi anephethini. Lapho okokusebenza namapayipi kudingeka kuhlolwe njalo, amapuleti ensimbi anephethini aphansi kufanele asetshenziselwe ukunciphisa ingozi yezinto eziwayo ezingase zenzeke ngesikhathi sokuhlolwa nokulungiswa. Amapuleti ensimbi anephethini kufanele asetshenziselwe izinkundla zokubuka eziphakeme (>10m) zesifunda ukuze kuncishiswe umthelela wokwesaba kwabantu ukuphakama.

Isikhathi sokuthumela: May-29-2024